EN

8

Maintenance

The following suggestions deal with the daily maintenance of the chain saw. If they could not be

exhaustive, contact an authorised service centre.

If the replacement of the supply cord is necessary, this has to be done by the manufacturer or his

agent in order to avoid a safety hazard.

1)

Ensure that the electric power lead (9) is not damaged.

2)

Ensure that the motor and air slots (8) are free and unobstructed.

3)

Check that the lubrication system is adequate.

4)

Clean the chain brake and ensure that it works properly.

5)

Turn the bar over every day.

6)

Check the bar wear.

7)

Ensure that the oil flow hole is unobstructed.

8)

Clean the chain guide on the bar.

9)

Check the chain tension, sharpen the blades and check their conditions, eventually removing

irregularities.

10)

Check the guide bar sprocket condition.

11)

Ensure that the oil reservoir and the oil filter are clean.

This chain saw meets all current legislation requirements, in order to avoid injuries while

repairing; every repairing has to be done by qualified staff in an authorized service centre.

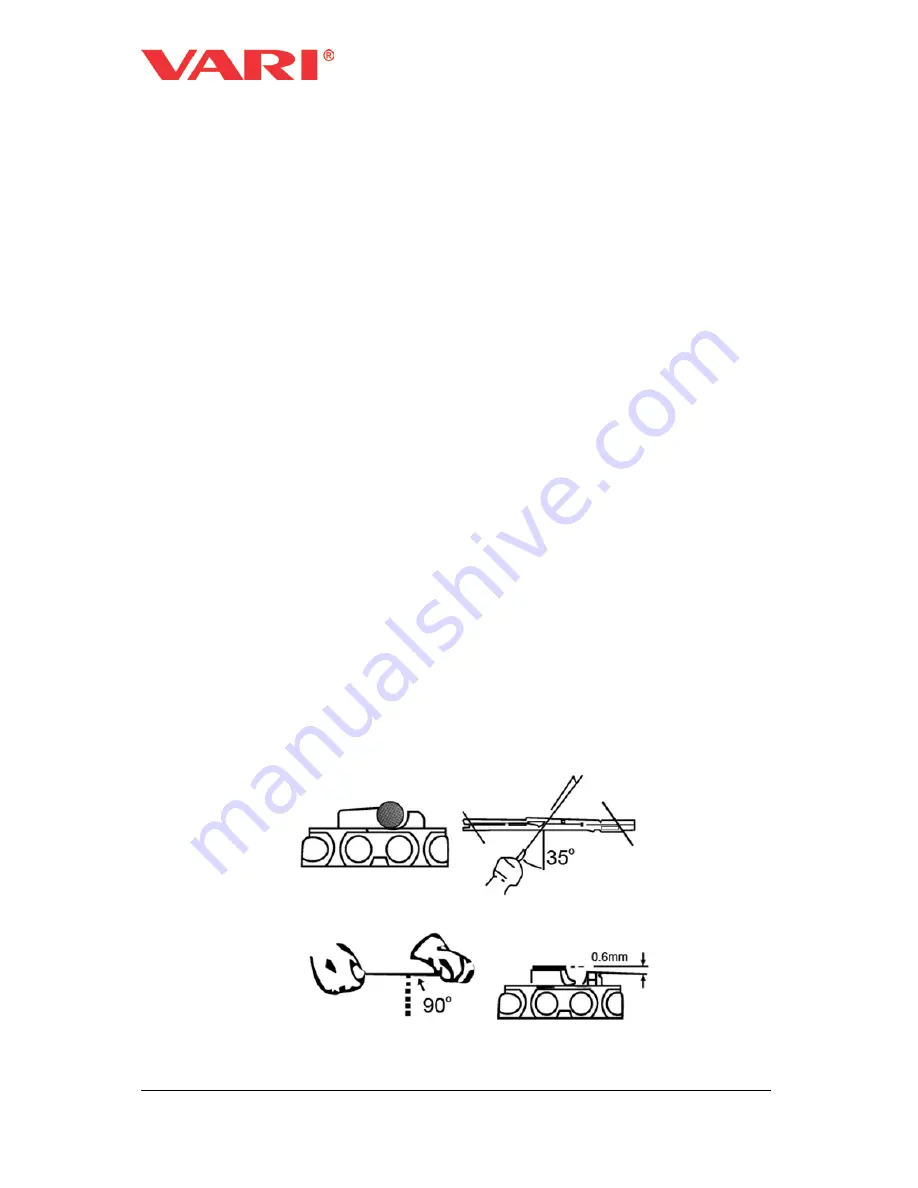

Chain sharpening

1)

Disconnect the cord from the mains supply.

2)

Wear protective gloves.

3)

Ensure the chain is correctly tensioned and not too loose.

4)

Engage the chain brake (10) to block the chain on the bar when sharpening (“0”).

5)

Use a round file for chain sharpening, diameter equivalent to 1,1 times the cutting tooth

depth.

6)

File at a horizontal angle, 35° to the bar.

7)

File from inside towards outside of the tooth only.

8)

Sharpen each tooth equally by using the same number of strokes.

9)

File at an angle of 90° to the bar.

10)

Check the safety depth gauge height every 5 chain sharpening. Use depth gauge measuring

instrument to check the height of the depth gauge.