KC-435

20

1.6

Transportation and storing

1.6.1

Transportation

!

The engine must always be off and the safety cover must

be put on the cutting tool during transport.

During transport, the brush cutter/trimmer must be

properly secured and fastened in such a way that it can’t

come loose and the oil filling can’t run out of the engine.

1.6.2

Storing

If the machine won’t be used for more than 2 months, it is recommended to take following measures:

Drain fuel from the fuel tank and let the engine run until the rest of the fuel in the carburettor is

consumed.

Unscrew the spark plug and put a few drops of clean engine oil into the combustion space of the cylinder.

Gently pull the starter rope several times, so that the oil can be spread, and install the spark plug back.

Completely clean the grass rests off the whole brush cutter/trimmer, especially from the engine cooling

fins and from the gearbox surroundings.

Spray the surface of metal parts of the brush cutter/trimmer with a thin film of preservative oil in spray

can (such as GT85, WD40, etc.) It prevents corrosion.

Veil the brush cutter/trimmer and store it in a dry place.

If it is necessary to store the brush cutter/trimmer in vertical position, store it with the engine facing

down. This avoids possible engine fall.

1.6.2.1

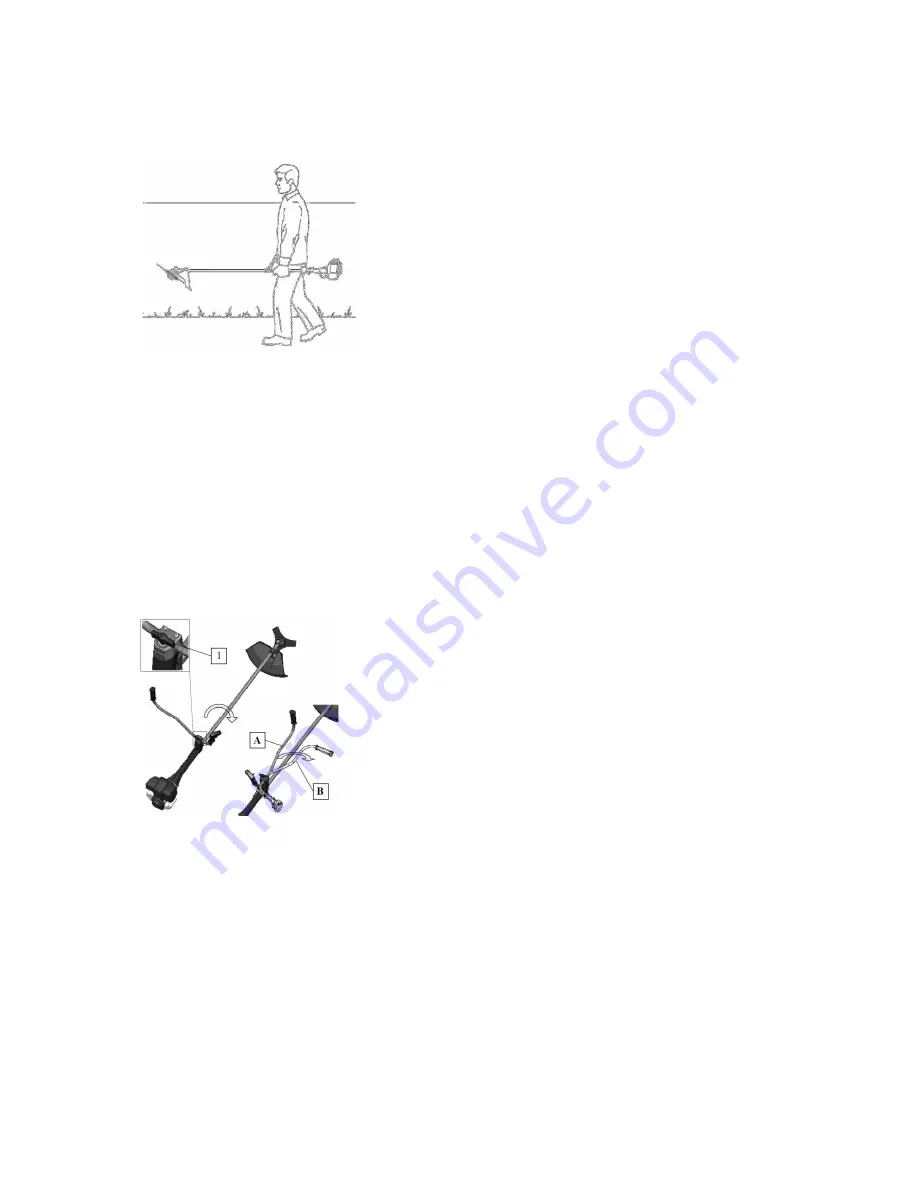

Tilting the handlebars

It is possible to tilt and turn the handlebars of your brush cutter/trimmer

to a storage position for easier storing. The tilting procedure is described below.

Turn the handlebars in the clockwise direction only (as seen

from above).

Never tilt the handlebars for more than ¼ revolutions.

Loosen the wing nut (1) and turn the handlebars to position

A

,

after that you can alternatively tilt them into position

B

.

Tighten the wing nut.

1.6.3

Storing the fuel

Store the fuel only in containers intended for petrol storing. Such containers prevent the petrol from

contamination by substances contained in the container walls and thus avoid possible engine damage.

Such polluted, old or degraded fuel can cause clogging of the carburettor, seizure of the distribution

system and subsequently serious damage to the engine – such problems can’t be and won’t be covered by

the warranty. The quality of unleaded petrols is strongly depending on storing conditions, petrol age, etc.

Most unleaded petrols lose their qualities during 3-4 weeks. Store only the necessary quantity of the fuel

which can be used within a month from the purchase at the latest.

The manufacturer bears no responsibility for defects on the fuel system caused by using incorrect type of fuel, fuel

which is polluted and/or otherwise contaminated and degraded, old and/or otherwise deteriorated by age or incorrect

storing.

Such defects can’t be covered by the warranty.