Operating Instruction Manual

Page 7

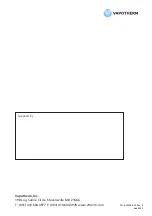

Mounting pole

Flowmeter

Air line

Oxygen line

Vapotherm

2000i

Delivery tube

Sterile

Water

Bag

Simple, easy

to use touch

control panel

and information

screen.

Vapor transfer

cartridge

Note: System specification

and front panel layout

may vary.

VSS-1

Spike set

Air/Oxygen

Blender

Section 4

Set-up

4.1

The 2000i Unit

1. The back of the 2000i has an IV pole clamp that

enables IV pole attachment.

2. The unit should be mounted on a sturdy IV pole

approximately two feet from the top of the

pole to facilitate ease of access and proper

flow from sterile water system.

3. If using an oxygen blender, mount the blender

above the Vapotherm 2000i on the IV pole.

4. Connect blender hoses into both air and

oxygen wall connections.

5. Plug Vapotherm power cord into a hospital

wall power outlet.

WARNINGS:

Aseptic technique (including proper hand washing

and avoiding direct hand contact with connection

points) should always be followed when setting up

and operating the Vapotherm 2000i.

The medical gas source is external to the Vapotherm

2000i. Always verify the integrity of the medical gas

source and utilize bacterial filters if necessary.

Closed system components (VSS-1, Vapor Transfer

Cartridge and Patient Delivery Tube) should not be

opened in patient care area.

4.2

Selecting the Vapor Transfer

Cartridge

Vapotherm provides both a high flow cartridge

(VT01-AS) and a low flow cartridge (VT01-BS).

• The high flow cartridge (VT01-AS) should be

used with the pediatric cannula with an

operational flow range of 5 – 20 liters per minute

(lpm) or with adult sized cannula with an

operational flow range of 8– 40 lpm.

• The low flow cartridge (VT01-BS) should be

used with the neonatal, premature, infant, or

intermediate sized cannula with an operational

flow range of 1– 8 lpm.

WARNINGS:

Do not exceed maximum operational flow rates of 40 lpm

for the high flow cartridge (VT01-AS) and 8 lpm for the low flow cartridge (VT01-BS).

Ensure that the correct cartridge is inserted before operating.

Section 3

About the Vapotherm

®

2000i

The Vapotherm 2000i warms and humidifies flows of air, oxygen or medical gas blends for delivery to a

patient, by nasal cannula or Vapotherm approved interface.Warming and humidification of breathing gas

occurs in a Vapor Transfer Cartridge, where air and water are separated by a membrane permeable to

water vapor. The membrane consists of microtubules constructed of polysulfone material. The membrane

meets HIMA (Health Industry Manufacturers Association) standards on filters for sterilizing liquids and has

been shown to effectively exclude bacteria from crossing from the water circulation to the gas flow.

The warmed humidified gas stream reaches the patient via a patented triple lumen Patient Delivery Tube.

Humidified gas flow is delivered through the center lumen. The outer lumens contain water which is

warmed via an internal heater and propelled through the system via an internal pump (

See schematic,

fig. 1).

This maintains breathing gas temperature and minimizes condensation. The final patient interface

is a Vapotherm nasal cannula or approved interface configured to minimize resistance and heat loss.

NOTE:

The water circuit and gas circuit of the Vapotherm 2000i do not come in contact with each other.

Respiratory gases are supplied to the Vapotherm™ 2000i from an external gas supply, typically through a

standard wall-mounted flow meter connected to the hospital medical gas supply. Gas flow rate is controlled

by the external flow meter or medical gas blender. There are no flow controls on the Vapotherm™ 2000i.

Connections for gas flow and water are made via the rear panel. All Vapotherm 2000i controls are on the

front panel of the device.

WARNING:

Use of patient interfaces not recommended by Vapotherm may cause safety concerns or

affect the performance of the device.

Operating Instruction Manual

Page 6

Fig. 1

Simplified System Diagram

Water Reservoir

Pump

Heater

Heated

Delivery

tube

Breathing Gas to Patient

Breathing Gas

Inlet

Vapor

Transfer

Cartridge