PAGE 2

PRINTED IN THE U.S.A.

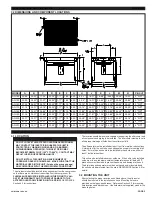

ASSEMBLY, LEG INSTALLATION

SECTION 2

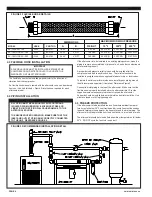

MAXIMUM CAPACITY (SCFM)

Rated capacities are based on the following conditions: Inlet and approach temperature at inlet pressures 80 to 125 PSIG.

Approach Temperature:

The number of degrees above the temperature of the cooling medium (in this case ambient air) to

which the aftercooler reduces the compressed air. A higher approach does

not

mean better performance.

INLET TEMP.

APPROACH

TEMP.

O

F

MODEL

AC-140

AC-150

AC-160

AC-170

AC-180

AC-190

AC-200

AC-210

AC-220

15

520

890

1178

1475

1950

2420

3000

3580

4140

20

605

1025

1360

1710

2260

2800

3470

4120

4800

5

175

308

415

520

710

870

1090

1295

1530

10

375

560

754

950

1290

1580

1980

2360

2785

15

430

760

1020

1290

1720

2140

2680

3200

3760

20

500

880

1180

1460

1950

2460

3100

3710

4320

5

160

290

390

490

660

820

1035

1243

1460

10

300

545

712

900

1200

1490

1880

2260

2660

15

400

725

950

1200

1600

2000

2500

3000

3500

20

464

840

1100

1380

1860

2300

2870

3450

4015

10

250

450

588

735

965

1210

1426

1794

2090

15

340

605

785

980

1290

1595

1980

2360

2760

20

396

701

910

1130

1480

1840

2270

2715

3200

5

125

225

280

355

460

572

705

840

950

10

235

410

520

650

840

1040

1290

1530

1740

15

305

540

690

865

1135

1400

1725

2040

2350

150

O

F

200

O

F

350

O

F

250

O

F

300

O

F

MAXIMUM PRESSURE DROP LESS THAN 3 PSI.

2.1 INSTALLING THE LEGS

This unit was shipped without the legs installed.

The legs should be installed before placing the

aftercooler in the piping system. Carefully lift and

support the unit several feet from the floor.

Position the legs against the unit and fasten them

in place using the fasteners provided. Make sure

the fasteners are tightened in place.

FIGURE 1 LEG INSTALLATION DETAIL

SPECIFICATIONS AND DIMENSIONS

SECTION 3

3.1 SPECIFICATIONS

WEIGHT

AC-140 ........ 120 LBS

AC-190 ........... 600 LBS

AC-150 ........ 170 LBS

AC-200 ........... 625 LBS

AC-160 ........ 330 LBS

AC-210 ........... 645 LBS

AC-170 ........ 450 LBS

AC-220 ........... 750 LBS

AC-180 ........ 515 LBS

DIMENSIONS .............. See Section 3.2

INLET/OUTLET CONNECTIONS

AC-140 ............ 2" NPT (F)

AC-190 ............... 4" NPT (F)

AC-150 ............ 2" NPT (F)

AC-200 ............... 4" NPT (F)

AC-160 ............ 3" NPT (F)

AC-210 ............... 4" NPT (F)

AC-170 ............ 3" NPT (F)

AC-220 .............. 4" NPT (F)

AC-180 ............ 3" NPT (F)

MAXIMUM WORKING PRESSURE

ALL MODELS .................. 250 PSIG

MAXIMUM WORKING TEMPERATURE

ALL MODELS .................. 350

O

F

MATERIALS OF CONSTRUCTION

CABINET ......................... Steel with baked enamel finish

FAN GUARD ................... Steelwith baked enamel finish

FAN ................................. Polypropylene blades with aluminum hub

CORE .............................. Aluminum

MOTOR ........................... TEFC

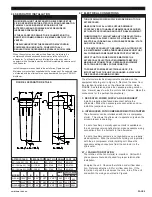

MOTOR SPECIFICATIONS AND DATA

See Wiring Diagram, Figure 5 on page 6.

FAN DATA

(AMBIENT AIR FLOW)

AC-140-6 ......................... 2200 SCFM

AC-140-7 ......................... 230V, 1825 SCFM 460V, 2200 SCFM

AC-150-6 ......................... 3600 SCFM

AC-150-7 ......................... 230V, 3025 SCFM 460V, 3600 SCFM

AC-160-6 ......................... 4700 SCFM

AC-160-7 ......................... 4700 SCFM

AC-170-6 ......................... 7000 SCFM

AC-170-7 ......................... 7000 SCFM

AC-180-7 ......................... 9700 SCFM

AC-190-7 ......................... 11000 SCFM

AC-200-7 ......................... 14000 SCFM

AC-210-7 ......................... 17500 SCFM

AC-220-7 ......................... 17500 SCFM

AC-140-6 thru AC-160-6 ...... 115/230-1-60

AC-170-3 ............................... 230-1-60

AC-140-7 thru AC-220-7 ...... 230/460-3-60

ELECTRICAL REQUIREMENTS

10

384

650

871

1090

1440

1790

2220

2650

3064

20

355

625

780

990

1300

1610

1980

2350

2700

5

135

245

320

405

530

660

784

985

1150

5

210

355

480

600

790

980

1220

1450

1680