6

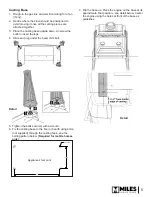

Casting Side Panels

1. On the casting side panels, release the top and

bottom screws.

2. Drop a hinge pin on the back corner of base and

drop the side panel on the pin.

3. Rotate the panel towards the engine.

4. Repeat with the other casting side panel.

Fixing Casting Side Panels & Engine

1. Adjust the position of the engine to locate the top

and bottom screws of the side panels into the

slots of the engine’s side bracket. Tighten the top

and bottom screws.

2. Adjust the engine as required and fi x it to the

casting base at bottom of its side brackets with the

nuts and bolts provided.

Top Spar

1. Position the top spar on the side brackets located

between the engine and the cast sides.

2. Fix the spar with two 3/8” pre-assembled screws

provided.

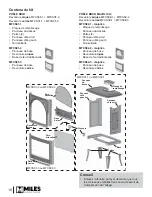

Complete engine installation

Refer to the engine installation manual for the following

steps.

1. Reposition the lighting instructions plate, remote

control receiver and connect gas line to the inlet

pipe.

2. Install the fan, if used, and convert the top outlet to

a rear outlet or co-linear outlet if necessary.

3. Install venting system.

4. Connect the gas and install the logs.

5. Refi t the window and the hot glass warning plate.

6. Set up the remote control and check operation.

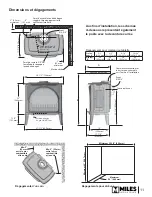

Front Installation

Hook the cast front to the side brackets located

between the engine

and the cast sides.

Cast front

Hook

Details

Engine

Side bracket

2

3