BCs160VA

Nov. 15, 1997

SMART-PULP

Smart Consistency Transmitter

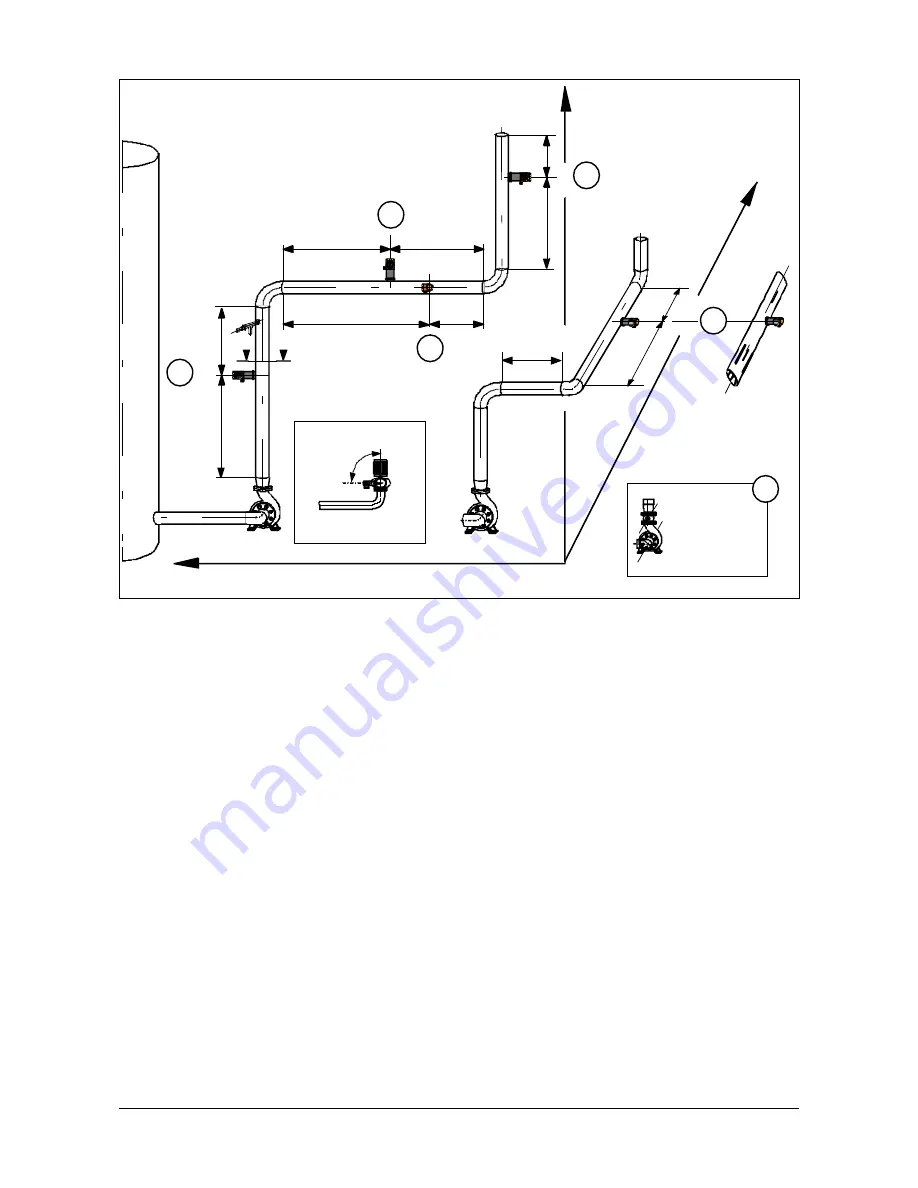

Figure 1.1.2a Preferred mounting locations for SMART-PULP in pipework

1.1.2 Selecting the mounting location

Preferred mounting locations: 1. A, 2. B1, 3. B2

or C (D when pipe turns upward again).

Important considerations:

A. This is the preferred location in terms of the

control loop’s lag time. If the required length of

straight pipe (L1 + L2) is not provided, you can use

an installation tube (Fig. 1.1.2b) that can be welded

in place immediately after conical expansion.

NOTE! The transmitter should be mounted at 90

O

angle to the pump axis (section E-E).

If the vertical section is shorter than the installation

tube or if accessibility is a problem, proceed to

alternative B1.

B1. In this alternative you install the transmitter on

the side of the line to prevent possible air from

disturbing the measurement. Notice that straight

section L1 before the transmitter is 50% longer than

in alternative A. If the straight section is too short,

you can use an installation tube or proceed to

alternative B2 or C.

B2. This method may be considered if the straight

length of horizontal pipe is too short for alternative

B1. Installation on the top side of the pipe always

requires careful consideration, because a substantial

buildup of air in the pipe may affect the

measurement accuracy. We do not recommend this

installation method.

C. You may consider this option when horizontal and

vertical sections before the transmitter are too short.

The double bend before the measurement point will

cause problems when L’ < L1. The whirling flow

produced by the double bend has to be eliminated

with installation tube. In addition, you have to

consider the control loop’s lag time which is

considerably longer in this alternative than in

alternative A.

D. In this method you install the transmitter on the

side of a pipe bend’s outer curve. Distance from pipe

bend is L1. Measurement lag: refer to C.

Other considerations:

F. If a globe valve that will not be continuously fully

open has to be installed between pump and

transmitter, the valve’s axis must be parallel to the

pump’s axis to eliminate whirling flow. The valve

manufacturer’s specifications must be taken into

account.

NOTE! Do not change the pipe diameter between

the pump's conical outlet section and the

transmitter's mounting lo L2 distance.

3

A

B2

B1

C

D

F

Valve and

pump axes

parallel

90

o

Section E-E

SMART-

PULP

axis

E

E

L1

L2

1.5 x L1

L2

L2

L1

L'

L2

L1

L2

L1