Thermo DC 200

Control elements

21

Recalling/erasing preset times

Repeatedly press the

button until the desired memory location is

displayed.

To erase the preset time, press the

button several times until the

time of the day is displayed instead of the memory location.

Programming duration of operating time

The heater must be switched off. Press the

button for 3 seconds -

operating time is flashing - and set the desired operating time (10 to 120

minutes) using the

and

buttons.

Setting the remaining operating time

Set the desired remaining operating time (1 to 120 minutes) using the

and

buttons. The remaining operating time refers to the time the

heater still continues to remain in operation. It can only be changed

while the heater is in operation and the ignition switched off.

Setting the wake-up time

A wake-up time can only be programmed on the standard digital timer.

The wake-up time is not bound to a specific day of the week. Repeatedly

press the

button until the bell symbol

appears on the display.

Set the desired wake-up time using the

and

buttons. The alarm

clock turns off after 5 minutes or when one of the buttons is pressed.

Recalling/erasing the wake-up time

Repeatedly press the

button until the bell symbol

appears on

the display - read off wake-up time. To erase the wake-up time: press

the

button until the bell symbol

is no longer visible on the

display.

Remote control

Possible by means of an optional external "instant heating" button

Vehicles with ADR equipment

On ADR vehicles it is not possible to program a preset starting time. The

remaining time is shown on the display while the heater is in operation.

The clock can be set. The alarm clock function can be programmed on

the standard digital timer.

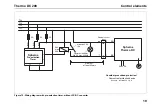

8.3. Activation via mains power

If you bridge the contacts of the control line, the heating system is acti-

vated when mains power is applied.

8.4. Operation indicator

For monitoring there should be an operation indicator provided at the

vehicle, which displays the status of the switching signal/heating

system.

If the operation indicator is integrated into the power circuit for external

control, it may require a current of max. 250mA. Only suitable lamps for

the voltage range of 18 - 30V are to be used (ref. also para. 8.1, Fig. 11

and 12).

Summary of Contents for THERMO DC 200

Page 4: ...IV Thermo DC 200...

Page 34: ...Technical data Thermo DC 200 30 For notes...

Page 35: ...memos...