4 System conditions

12

Set-up instructions 0020200969_07

4.4.5.2 ecoFIT

Air/flue system

Article number

VUW 256/6-3 (H-GB) ecoFIT pure 825

VUW 306/6-3 (H-GB) ecoFIT pure 830

VUW 356/6-3 (H-GB) ecoFIT pure 835

VUW 256/6-3 (H-GB) ecoFIT sustain 825

VUW 306/6-3 (H-GB) ecoFIT sustain 830

VUW 356/6-3 (H-GB) ecoFIT sustain 835

VU 126/6-3 (H-GB) ecoFIT pure 612

VU 156/6-3 (H-GB) ecoFIT pure 615

VU 186/6-3 (H-GB) ecoFIT pure 618

VU 256/6-3 (H-GB) ecoFIT pure 625

VU 306/6-3 (H-GB) ecoFIT pure 630

VU 126/6-3 OV (H-GB) ecoFIT pure 412

VU 156/6-3 OV (H-GB) ecoFIT pure 415

VU 186/6-3 OV (H-GB) ecoFIT pure 418

VU 256/6-3 OV (H-GB) ecoFIT pure 425

VU 306/6-3 OV (H-GB) ecoFIT pure 430

VU 356/6-3 OV (H-GB) ecoFIT pure 435

Max. concentric pipe length

1)

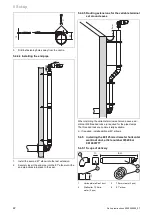

Horizontal wall/roof duct

303209

0010035777

25 m

plus 1 x 87° elbow

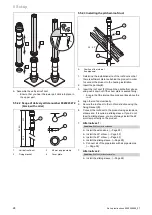

Vertical roof duct

303200

25 m

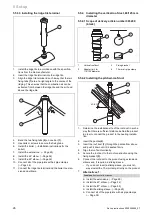

1) The inclusion of additional elbows in the flue system reduces the pipe length as follows:

–

By 1.0 m for each 45° elbow

–

By 2.5 m for each 87° elbow