13

ecoTEC plus 937 installation and maintenance manual

e

Danger!

Danger of death by electric shock!

If a room-sealed combi boiler is installed in a

room with a bath or a shower, the electrical

switches and the boiler controller, which operate

at mains voltage, must be mounted in locations

where any person in the bath or in the shower

cannot reach them.

In the event of installation in unusual locations, special

provisions may have to be made. Detailed instructions

for this can be found in BS 5546 and in BS 6798.

The ecoTEC plus 937 must be mounted on a flat, vertical

wall which is sufficiently strong to hold the weight of the

shift load storage tank and the combi boiler.

It is possible to mount onto a wall made of flammable

material if the regulations of the Local Authority and the

legal building regulations are fulfilled. In this case

however, the unit would have to be mounted in a

specially made enclosure. (You can also use an existing

cabinet or existing enclosure as long as it can be

modified accordingly to suit the new application.)

Further details concerning the fundamental

characteristics when modifying existing cabinets or

enclosures, including the requirements for ventilation,

are described in BS 6798.

h

Note!

If the boiler is to be installed in a half-timbered

house, the installation must be undertaken in

accordance with the Institute of Gas Engineers

Publication IGE/UP/7/1998 "Guide for Gas In-

stallation in Timber Framed Housing".

Note!

If the boiler is to be installed in an airing

cupboard it is not required to separate the

boiler with a non-combustible partition.

However installation and servicing clearances

must be maintained, and the appliance kept

clear of any clothing.

Please note the following instructions before choosing

where to install the boiler:

a

Caution!

Danger of damage to the unit from the effects

of frost!

Do not install the shift load storage tank and

combi boiler in rooms where there is a danger of

frost.

Caution!

In rooms with aggressive damp or dust the

combi boiler must be operated independent of

the ambient air.

Make sure that, when selecting the installation location

and when operating the unit, the combustion air is free

from chemical substances which contain fluorine,

chlorine, sulphur etc. Sprays, solvents and cleaning

agents, paints, adhesives etc.can contain substances of

this type which can cause corrosion in the flue gas

system, in the worst case even if the unit is operated as

an open vent appliance. Particularly in hairdressing

salons, lacquering and finishing, cleaning facilities, the

appliance must be operated independent of the ambient

air! Otherwise, a separate installation room is required

to guarantee that the combustion air supply is free from

the afore mentioned substances.

3.5 Gas

supply

The gas provider must guarantee the availability of an

adequate gas supply. The connection of a gas meter in

the supply line is only permitted when carried out by the

gas provider and a company appointed by him. If there is

an existing gas meter you must check that it is suitable

for the required gas rate.

Installation pipes should be fitted in accordance with

BS 6891. In IE in accordance with the current issue of

IS 813. The pipework between the gas meter and the

combi boiler must be of an appropriate size. Do not use

any pipes that are smaller than the connection to the

combi boiler (22 mm). The entire installation must be

checked for leaks and purged in accordance with

BS 6891.

3.6

Flue pipe

d

Danger!

Vaillant appliances are only system-certified if

genuine Vaillant flue pipes are used. Only use

genuine Vaillant flue pipes. Malfunctions can

occur if you use other accessories. These may

result in damage and injury. You will find a list

of genuine flue pipes in the Vaillant installation

manual for flue pipes.

The CE mark is valid only if the appliance is

operated with Vaillant flue pipes.

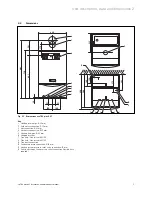

3.6.1

100 mm standard flue duct

667

87

65

30

74

48

Fig. 3.2 Item No. 303 933

General requirements 3