page 11 of 17

Documents are only to be used and distributed completely and unchanged. It is strictly the users´ responsibility to check

carefully the validity of this document with respect to his product. manual-no.: 999039 / 16/12/2009

Cleaning the gauge head

The gauge itself is maintenance-free.

➨

➨

➨

➨

➨

Only VSP 5

: Using small screw driver or pencil tip, release locking ring in gauge head connection and

remove protective filter with shim, keep locking ring.

➨

➨

➨

➨

➨

Fill the gauge head chamber with a solvent (e. g. benzene) and allow sufficient cleaning time. Observe

all regulations concerning usage and disposal of solvents!

➨

➨

➨

➨

➨

Drain the solvent and dispose of in accordance with regulations, repeat cleaning if necessary.

➨

➨

➨

➨

➨

Rinse the gauge head chamber several times with alcohol in order to remove all solvent residues.

➨

➨

➨

➨

➨

Allow the pressure transducer to dry.

➨

➨

➨

➨

➨

Only VSP 5:

Assemble protective filter and locking ring, replace protective filter if necessary.

➨

➨

➨

➨

➨

Readjust gauge head if necessary.

Note:

The gauge head

VSP 5

can be used without protective filter, if only the protective filter is not compatible

with the pumped media (see “Technical data“).

If the vacuum system is contaminated (oil, particles etc.):

☞

Replace the protective filter (cat. no.: 63 87 29) in the gauge head VSP 5 if necessary.

➨

➨

➨

➨

➨

Using small screw driver or pencil tip, release locking ring in gauge head connection and remove

protective filter with shim, keep locking ring.

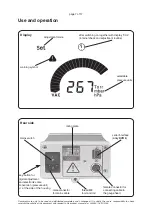

Readjustment

Readjusting the gauge head VSP 5

Readjustment at atmospheric pressure can be performed easily. Readjustment “vacuum“ at a pressure

< 5 x 10

-4

mbar should only be performed, if that vacuum range can be reached with a vacuum pump

available. Readjustment under vacuum is only necessary when, due to aging or contamination of the

filament, incorrect readings are observed. Clean a contaminated gauge head prior to readjustment.

Adjustment at atmospheric pressure:

➨

➨

➨

➨

➨

Vent vacuum system or gauge head, make sure, that gauge head is exposed to atmospheric pressure.

➨

➨

➨

➨

➨

Push key-button at the side of the housing with a pencil tip or a small screw driver. Status indication

adjustment (”Set”) is displayed.

➨

➨

➨

➨

➨

Push key-button again in order to adjust pressure reading to atmospheric pressure. Status indication

adjustment vanishes.

Instructions for repair with directions for repair and spare parts list is available on

request.

☞

The instructions are for trained service people.