12

QUICK START

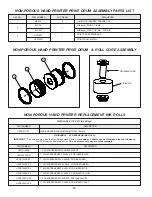

5 - Reinstall the print drum on the Hub Assembly and re-

place the Print Drum Retaining Knob.

FIGURE 20

FIGURE 21

4 - When using the smaller individual characters to make up a

code message, use the Type Blocking Kit included with your

coder to support the leading and trailing ends of the type

as shown.

Characters with only a 2 or 3 rib backing do not have the stabil-

ity of the larger sizes when snapped into the drum cover. Add-

ing the rib backed type blocks on either side of the code will

provide added stability. The Type Blocks are not as thick as the

Type and will not pick up ink from the Transfer Roll.

The print drums on indexing coders always return to the same rotational or “indexed” position after every print is

applied and the print drum is lifted off the surface of the material being printed. In order to ensure that fresh ink is

applied to the die faces on every printing cycle, the dies should be positioned rotationally upstream of the Transfer

Roll when the print drum is in the indexed position.

ADJUSTING THE DIE POSITION ON INDEXING PRINTERS

1 - To position the printing dies, slightly loosen the Print

Drum Knurled Nut. Rotate the Print Drum as neces-

sary to bring the leading edge of the die into the posi-

tion indicated and then hold the Print Drum stationary

while tightening the Print Drum Knurled Nut to lock

the Print Drum in place.

FIGURE 22

When the printer is used with the leading edge of the printing

die positioned as shown, the printing dies are immediately ro-

tated past the anilox roll where the ink is applied and then the

impression is immediately transferred to the surface of the

material being printed.

PRINT DRUM ROTATION

KNURLED NUT

DIE LOCATION

LEADING EDGE OF

DIE HERE

TRANSFER ROLL

Summary of Contents for HPNP-100

Page 25: ...25 ...