MODELS 3900F & 3900M - Butterfl y Valve with Manual Gear Operator

GENERAL

Butterfl y valves are a signifi cant component of any water distribution system or treatment plant operation. Valve

failure caused by faulty installation, improper operation, or maintenance in these systems could result in dam-

age, downtime, and costly repairs. In buried or underground installations, problems or malfunctions can result in

extensive an costly excavation to correct or eliminate the problem. Many problems with butterfl y valves can be

traced to improper installation, or maintenance procedures.

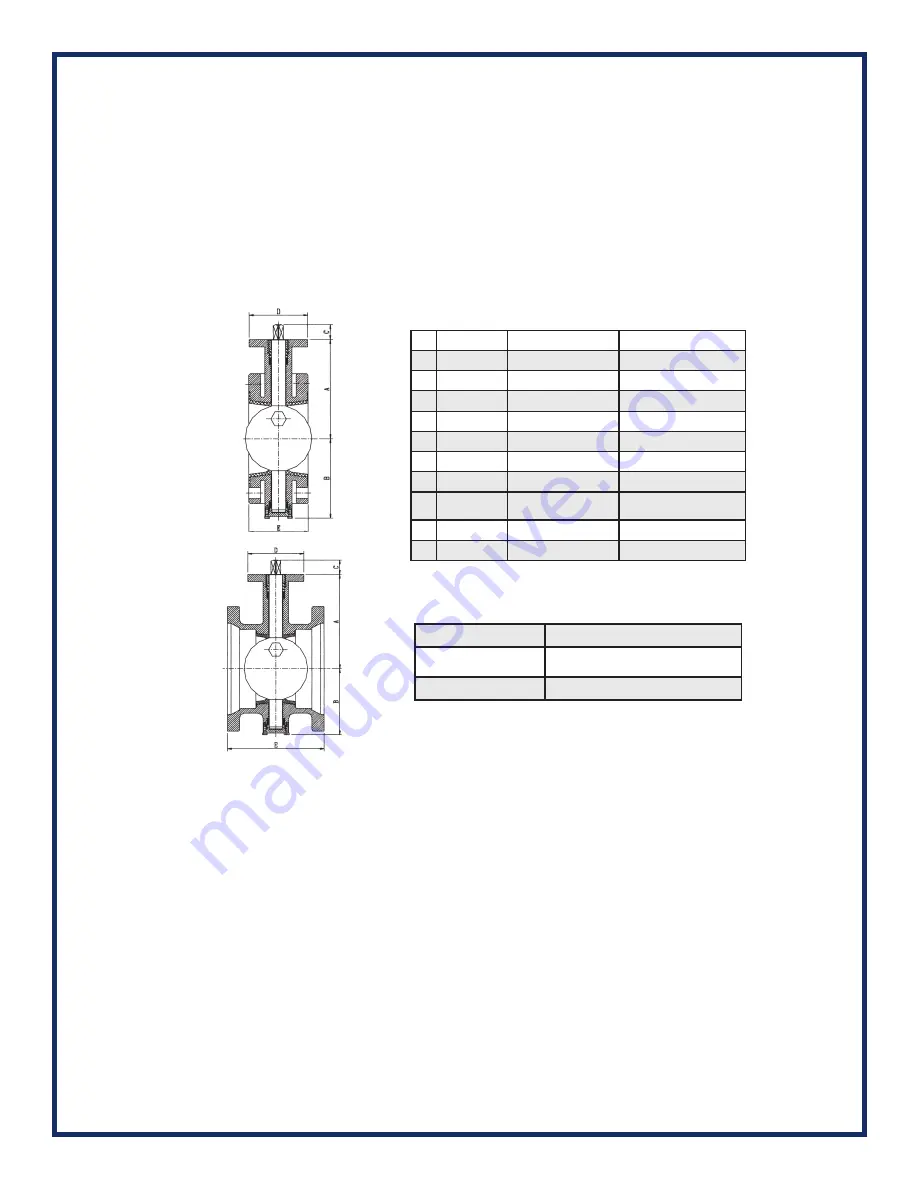

MATERIAL LIST/PRESSURE AND TEMPERATURE:

No.

Part Name

Material

ASTM Spec.

1

Stem

Stainless Steel

AISI 420

2

Spacer

Brass

ASTM B16 C36000

3

Packing

EPDM or NBR

-

4

Bushing

Brass

ASTM B16 C36000

5

Body

Ductile Iron

ASTM A536 65-45-12

6

Bearing

Tefl on

-

7

Seat

EPDM or NBR

-

8

Disc

Ductile Iron

(with SS316 Edge)

ASTM A536 65-45-12

9

Cover Plate

Ductile Iron

ASTM A536 65-45-12

10 Lock Washer

Carbon Steel

AISI 1045

Nominal Pressure

250 Psi

Working Temperature

EPDM: -10°C to 120°C

NBR: -10°C to 82°C

Suitable Media

Water, Oil, Gas

Flange x Flange

MJ x MJ

UNLOADING

Inspect valves on receipt for damage in shipment and conformance with quantity and description of the shipping notice and or-

der. Unload valves carefully to the ground without dropping them. On valves larger than 16 in. (400mm), use forklifts or slings

under the skids. On smaller valves, do not lift valves with slings or chain around the operating shaft, actuator, or through the

waterway. Lift these valves with eye bolts or rods through the fl ange holes.

STORAGE

If it is not practical to store a valve indoors, protect the valve and actuators from weather; the accumulation of dirt, rocks and

debris. When valves fi tted with power actuators and controls are stored, energize electric actuators or otherwise protect elec-

trical-control equipment to prevent corrosion of electrical contacts caused by condensation resulting from temperature varia-

tion. Do not expose rubber seats to sunlight or ozone for any extended period.

INSPECTION PRIOR TO INSTALLATION

Verify fl ange faces, joint-sealing surfaces, body seats, and disc seats are clean. Verify the bolts attaching an actuator to a

valve are tight, and if loose, tighten fi rmly. Open and close a valve to verify it operates properly and that stops or limit switches

are correctly set so that the valve seats fully. Close a valve before installing it.

Summary of Contents for 3900F Series

Page 5: ......