Unitary Products Group

7

035-15266-003 Rev. A (0804)

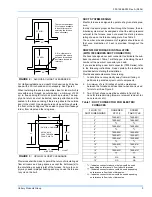

10. Flange plate shipped with 3500-7211* is mounted to the

furnace with eight (8) screws provided. Two (2) blunt

screws are for the holes in the front of the furnace. See

Figure 12.

11. If upflow adapter box kit 3500-5451* is not used, then

our optional filter bracket is provided with 3500-7211* kit.

This filter bracket maybe used to retain filter inside its

original location in the furnace.

12. Secure the top of the furnace to a structural member

using screws and the strap on top of the furnace. The

mobile home manufacturer may provide an equivalent

strap, if required, to secure the furnace.

13. If excessive movement is expected, then some blower

support is recommended.

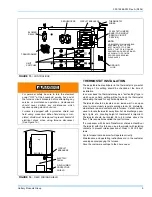

WIRING

Furnace wiring is complete except for the power supply and

the thermostat wires. See wiring diagram (or Table 2) for wire

and fuse size. See Table 2 for ground wire sizes. Thermostat

wires connect through side of furnace and should also be no

smaller than 22 gauge. Power wires can enter through the

side of the unit or through the auxiliary entrance, located in

the bottom of the unit. (See Figure 1). When bringing wiring

through the bottom of the furnace, cable connectors must be

installed to hold wiring in place and to relieve any strain on

the wiring. These connectors will also serve as a seal

between the furnace and the floor. Thus, additional sealing is

not required.

(Refer to the National Electrical Code, Canadian Electrical

Code and local codes for wiring material requirements.

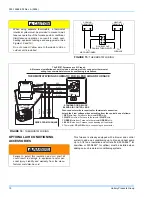

NOTE:

The furnaces are equipped with either one or two 60

amp circuit breakers. These circuit breakers protect

the wiring inside of the furnace in the event of a

short circuit. Additionally, these breakers provide a

means of disconnecting the power to the unit. The

circuit breakers in the furnace are not meant to pro-

tect the branch circuit wiring between the furnace

and the home's breaker panel. General wire and

breaker sizes are shown in Table 2. If sheathed

cable is used, refer to National Electrical Code,

Canadian Electrical Code and local codes for addi-

tional requirements concerning supply circuit wiring.

Electrical Data can be found in Table 4.

IMPORTANT -

All installation on field wiring must be

rated at 60ºC or higher. Please refer to the wiring diagrams

on the furnace or this book for more information.

*

Requires Jumper Bars (P/N 3500-3781*) - Dual Supply for U.S. Only.

Refer to National Electrical Code. Table 310-16 for Non-Sheathed Conductors.

+ Refer to National Electrical Code. Table 250-95 for Non-Sheathed Conductor Ground Wire.

FIGURE 12 :

BLOWER BRACKET AND DUCT FLANGE

ATTACHMENT

FLANGE

PLATE

(MOUNTED WITH

SCREWS)

EB SERIES

(UPFLOW

FURNACE)

DUCT

CONNECTOR

LINESET

KNOCKOUT

USE BLUNT

SCREWS HERE

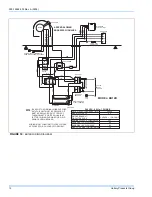

Table 2:

MODELS

EB23B

EB20B

EB17B

EB15B

EB12B EB10B

Single Branch Circuit Service *

2 Leads + 1 Ground CKT#1

Nominal Circuit Load - AMPS

94.0

84.0

70.7

64.1

50.7

44.0

Minimum Wire Size (90º)

#2

#3

#4

#4

#6

#8

Minimum Wire Size (75º)

#1

#2

#3

#4

#6

#6

Minimum Wire Size (60º)

#0

#1

#2

#3

#4

#6

Ground Wire Size +

#6

#6

#8

#8

#8

#10

Max. Fuse (or C.B.) - AMPS

125

110

90

90

70

60

Dual Branch Circuit Service

CKT #1

CKT #2

CKT #1

CKT #2

CKT #1

CKT #2

CKT #1

CKT #2

NOT

APPROVED

Branch Circuit Load - AMPS

47.3

46.7

44.0

40.0

47.3

23.4

44.0

20.1

Branch Circuit Min. - AMPS

59.2

58.4

55.0

50.0

59.2

29.3

55.0

25.2

Minimum Wire Size (90º)

#6

#6

#8

#8

#6

#10

#8

#10

Minimum Wire Size (75º)

#6

#6

#6

#8

#6

#10

#6

#10

Minimum Wire Size (60º)

#4

#4

#6

#6

#4

#10

#6

#10

Ground Wire Size +

#10

#10

#10

#10

#10

#10

#10

#10

Max. Fuse (or C.B.) - AMPS

60

60

60

50

60

30

60

30