7

Unitary Products Group

ROOF JACKS

FAILURE TO FOLLOW ALL VENTING IN-

STRUCTION CAN RESULT IN FIRE ASPHYXI-

ATION, OR EXPLOSION.

CAUTION:

Only use the appropriate roof jack.

See Figures 6 & 7 for correct application.

Do not exceed the maximum height as determined

from Figures 2 & 3. Installer should allow an addi-

tional 1-

1

/

2

” travel before the flue pipe assembly is

fully extended against the built- in stop. This pro-

vides an additional safeguard against the flue as-

sembly being pulled from the roof jack during trans-

portation or other stress conditions.

EXISTING FURNACE REPLACEMENT

If this furnace replaces an

exciting furnace

, do the fol-

lowing:

1. If a 2

nd

roof, roof cap or addition has been made to

the existing roof of the home,

remove the old roof

jack completely!... to avoid the possibility of an

improperly installed pipe or gaps in the old roof

jack, INSTALL A NEW ROOF JACK. Your ceiling

and roof height will determine the correct roof

jack to use. Refer to the vent selection table, of

the furnace installation instructions.

2. After unpacking the roof jack, check the rain caps.

Insure they are not damaged, tilted or crooked.

Do

not twist, crush or sit on the roof caps during

installation.

Damaged roof caps will cause improp-

er furnace operation. The furnace will not heat prop-

erly and could result in explosion.

3. Before inserting the roof jack into the furnace top, in-

spect the furnace flue and combustion air opening

for debris or insulation which might have fallen in

during pre--installation steps. Do not proceed unless

all debris have been cleaned out or removed.

4. After installing roof jack on furnace top collar, check

to make sure there is no gap in back or side between

the pipe collar and the furnace casing top.

5. Use only the pipes provided with the roof jack as-

sembly. Do not add to or adapt other sheet metal

pipes.

Do not cut, insert or add other pipes to this

assembly.

6. In no case should there be a gap between sections

of the flue pipe or the combustion air pipe. If neces-

sary to prevent excessive air leakage, the installer

should seal joints in the combustion air tube with alu-

minum type or other suitable sealant.

NEW HOME INSTALLATION

If this furnace is installed on a new home do the following:

1. Inspect the furnace top collars for signs of insulation

or ceiling debris which might have fallen in during

cutting of the ceiling and roof holes. Remove all de-

bris before continuing.

2. After unpacking the roof jack, check the rain caps.

Insure they are not damaged, tilted or crooked.

Do

not twist, crush or sit on the roof caps during

installation.

Damaged roof caps will cause improp-

er furnace operation. The furnace will not heat prop-

erly and could result in explosion.

3. Before inserting the vent pipe into the furnace top,

inspect the furnace flue and combustion air opening

for debris or insulation which have fallen in during

pre--installation steps. Do not proceed unless all de-

bris have been cleaned out or removed.

4. After installing roof jack on furnace top collar, check

to make sure there is no gap in back or side between

the pipe collar and the furnace casing top. If neces-

sary to prevent excessive air leakage, the installer

should seal joints in the combustion air tube with alu-

minum type or other suitable sealant.

INSTALLATION IN SNOW REGIONS

When the combustion air pipe inlet is covered or blocked

with snow, the furnace will not operate properly due to

the depleted combustion air supply.

Therefore, if the furnace will be located in regions where

snow accumulation on the roof exceeds 7” or in H.U.D.

Snow Load Zones, a roof jack extension (Part No.

7680B6541) is recommended.

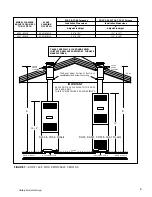

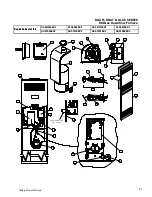

LOCATING AND CUTTING ROOF JACK

OPENING

To facilitate the proper installation of the roof jack, it is

very important that the roof jack opening in the ceiling

and roof be on the same vertical center line as the fur-

nace flue collar. See Figure 8.

Mark this location on ceiling and scribe a circle with a 5”

radius (10” diameter) around this mark. Cut opening for

roof jack through ceiling and roof.

(If furnace was in-

stalled during construction, cover furnace and flue

opening to prevent debris from entering flue when

hole is cut for roof jack.)

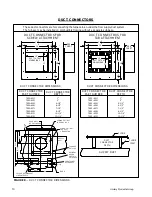

INSTALLING ROOF JACK IN ROOF

(See Figure 6 & 7 for Dimensional requirements.)

Insert roof jack into opening in the roof.

The roof jack should be secured to the furnace be-

fore roof flange (flashing) is secured to the roof.

This

will insure a better alignment of the flue pipe and furnace

flue collar. Caulk around and under roof flange to provide

a water tight seal, before securing roof jack flashing to

roof.

Summary of Contents for DLAS

Page 23: ...23 Unitary Products Group...