11

Unitary Products Group

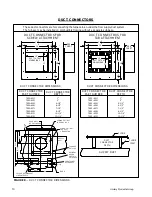

FIGURE 9 --

DUCT CONNECTOR SCREW

ATTACHMENT

SUPPLY DUCT

LOCATOR BRACKET

NAILS, FLAT HEAD SCREWS

OR STAPLES

SCREWS

FLOOR

FIGURE 10 --

DUCT CONNECTOR TAB

ATTACHMENT

SUPPLY DUCT

LOCATOR BRACKET

NAILS, FLAT HEAD SCREWS

OR STAPLES

FLOOR

BEND TABS UNDER

DUCT OPENING TO

SECURE TO THE

SUPPLY DUCT.

INSTALLATION OF SCREW ATTACHMENT

DUCT CONNECTOR

1. Make floor cut out as shown in Figure 8.

2. Determine the depth of the floor cavity from the sur-

face of the floor to the top of the supply air duct and

select the appropriate duct connector from the chart.

3. Place locating bracket (supplied with the duct con-

nector) to the back edge of the floor opening. See

Figure 9.

4. Apply a water based duct sealant to the 1/2” supply

duct attachment flange of the duct connector.

5. Determine which of the four positions the duct con-

nector best centers over the supply duct and insert

it through the floor cutout.

6. When properly aligned with the supply duct, secure

the duct connector to the floor with nails, flat head

screws or staples.

7. Use screws as required to secure the duct connector

to the supply duct.

8. Cut out the opening to the supply duct.

If sealant

was not used, the installer should tape the mat-

ing flanges to provide a good air seal.

NOTE:

Duct sealant and tape must be U.L. classified as

meeting HUD standard 3280.715 and U.L.

standard 181.

INSTALLATION OF TAB ATTACHMENT

DUCT CONNECTORS

1. Make floor cut out as shown in figure 8.

2. Determine the depth of the floor cavity from the sur-

face of the floor to the top of the supply air duct and

select the appropriate duct connector from the chart.

3. Place locating bracket (supplied with the duct con-

nector) to the rear of the floor area for the furnace.

See Figure 10.

4. Determine which of the four positions the duct con-

nector best centers over the supply duct and insert

it through the floor cutout.

5. Mark cut--out location on the supply duct and re-

move the duct connector.

6. Cut out the opening to the supply duct.

7. Bend tabs down through and back up under the sup-

ply duct.

8. Secure the duct connector to the floor with nails, flat

head screws or staples.

The duct connector is designed for use on ducts down to

12” in width. When using the connector on smaller width

ducts, there will not be sufficient clearance to bend the

tabs on two sides of the duct connector.

In such cases the tabs may be attached to the sides of

the duct by using sheet metal screws or other suitable

fasteners. Holes for sheet metal screws are provided in

three (3) tabs on each side of the duct connector. If more

than 3 tabs need to be used to provide a more secure and

air tight connection, the remaining tabs can also be fas-

tened to the duct with screws after drilling the required

screw holes.

If tape is used to provide a better air seal, it should be a

type approved by the applicable national or local codes.

Summary of Contents for DLAS

Page 23: ...23 Unitary Products Group...