PART III: OPERATION

25

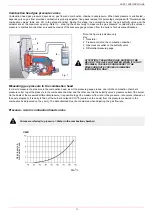

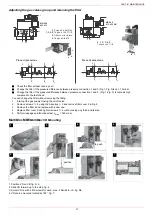

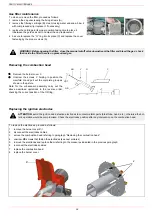

ADJUSTING AIR AND GAS FLOW RATES

Adjustments - brief description

The air and fuel rates adjustments must be performed at the maximum ouptput first (“high flame”): see the LMV related manual.

Check that the combustion parameters are in the suggested limits.

Check the flow rate measuring it on the counter or, if it was not possible, verifying the combustion head pressure by means of a dif-

ferential pressure gauge, as described on par. “Measuring the gas pressure in the combustion head”.

Then, adjust the combustion values by setting the “gas/air” ratio” curvepoints (see the LMV related manual).

Set, now, the low flame output (according to the procedure described on the “Siemens LMV manual”) in order to avoid the low

flame output increasing too much or that the flues temperature gets too low to cause condensation in the chimney.

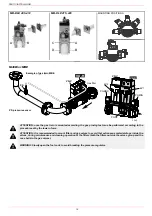

(First) Start-up preliminary operations - gas supply

Recommended actions to be carried out in sequence:

1

Check the burner and all its components are installed correctly

2

Check that all electrical and mechanical parts are connected correctly

3

Check that there is water or other vector fluids in the generator

4

Check that the ventilation gates/dampers in the plant are open and the stack is free

5

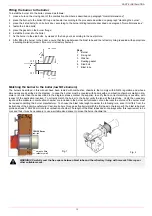

Connect the gauges used to adjust and check pressures on the incoming line and on the head, air and fuel side.

6

Open the thermostatic series and the safety chain

7

Turn the main switch on the panel front with the "ON/OFF" selector to position "ON".

8

Check the phase and neutral position is correct

9

Open the manual shut-off valves slowly, in order to prevent any water hammers that might seriously damage valves and pressure

regulator

10 Check the sense of rotation of the electrical motors

11 Bleed the line, getting rid of all the air in the pipe as far as the main gas valve

12 Ensure the pressure entering the main valves is not excessive due to damage to or wrong adjustment of the line pressure regulator

13 Ensure the gas supply minimum pressure is at least equal to the pressure required by the pressure curves - burnt gas flow

WARNING! During commissioning operations, do not let the burner operate with insufficient air flow (danger of

formation of carbon monoxide); if this should happen, make the fuel decrease slowly until the normal combustion

values are achieved.

WARNING! the combustion air excess must be adjusted according to the values in the following chart.

Recommended combustion parameters

Fuel

Recommended (%) CO

2

Recommended (%) O

2

Natural gas

9 ÷ 10

3 ÷ 4.8

LPG

11 ÷ 12

2.8 ÷ 4.3

DANGER! Venting the air from the piping must take place in safe conditions, avoiding dangerous concentrations

of fuel in the rooms. You must therefore ventilate the rooms and wait long enough for the gases to dissipate out-

side before switching on.

To ensure the proper operation of the flow sensors, the fuel/air pipes must be free of liquid residues such as oil

or water. Also, make sure that the silencer is installed on the air intake.

Summary of Contents for C83X

Page 42: ......

Page 43: ......

Page 45: ...Service manual AZL2x LMV2x 3x Burner Management System M12916CD Rev 3 4 03 2023 ...

Page 52: ...8 Parameters level heating engineer ...

Page 94: ...50 ERROR CODE TABLE ...

Page 95: ...51 ...

Page 96: ...52 ...

Page 97: ...53 ...

Page 98: ...54 ...

Page 99: ...55 ...

Page 100: ...56 ...

Page 101: ...57 ...

Page 102: ...58 ...

Page 103: ...59 ...

Page 104: ...60 ...

Page 105: ...61 ...

Page 106: ...62 ...

Page 107: ...63 ...

Page 108: ...64 ...

Page 113: ......

Page 114: ......

Page 115: ......

Page 117: ...IG FU B ...

Page 118: ......

Page 119: ......

Page 120: ......

Page 121: ......

Page 122: ......

Page 123: ......

Page 124: ......

Page 125: ......

Page 126: ......

Page 127: ......