OM-NGB 9

Operation

A. Controls

Operating controls are located on the front panel of the unit.

a.

The on/off switch starts the unit or shuts it off.

b.

The RESET indicator lights to show that the boiler has filled with water

and that the main burners can ignite.

c.

The start switch (momentary) lights the main burners. It also restarts

the unit if electrical power is interrupted, or if a low water condition in

the boiler disables the unit.

d.

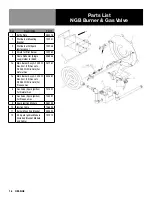

In addition to operating these controls, there are gas supply controls

located on the gas valve.

For NGB-3E:

When the control knob is “ON,” gas flows to the pilot, as

well as to the main burners.

B. Operating Procedure

a.

Turn on the water supply to the unit.

b.

Turn on electrical power to the unit.

c.

Turn on the gas supply to the unit, and turn on the gas valve.

Turn the control knob .on the gas valve to the “ON” position.

NOTE: The “ignition trial” period runs for approximately 90 seconds after the on/

off switch is turned ON. This means that if the pilot light does not light within

the “trial” period, the ignition system will automatically stop the gas flow and

terminate the ignition trial. If ignition is terminated, turn the switch off and then

“ON” again to repeat the trial. Normally, the pilot should light within five seconds

of turning on the unit.

d.

Turn the on/off switch on the front of the cabinet to “ON.”

1)

The amber light will come on.

2)

The boiler drain valve will close and the unit will fill with water.

3)

When the water reaches the “mid” probe, the red RESET light

will come on.

4)

Press the start switch.

5)

The green light in the switch will come on, the RESET light will

go off, and the main burner will light.

6)

When the water level reaches the “hi” probe, the water supply

to the boiler will shut off.

e.

After about 15 minutes, the pressure gauge will indicate that the

pressure is rising. When it reaches 9-1/2 PSI, the main burner will

shut off. Thereafter, the burner will periodically relight to maintain

the pressure at 9-1/2 PSI. The pilot light should stay lit when the

burner is off.

f.

To shut down the unit, turn the on/off switch to OFF. The unit will drain

automatically after it has cooled to about 170ºF. The unit turns off the

pilot light when the on/off switch is turned to OFF.

WARNING

ALL POTENTIAL USERS OF THE EQUIPMENT

SHOULD BE TRAINED IN SAFE AND CORRECT

OPERATING PROCEDURES.