- 17 -

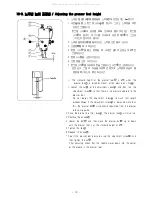

■

실 장력 스프링 장력

☞

실 장력 스프링①의 표준 장력은 0.25-0.35N 입니다.

1. 손가락으로 윗실을 실장력 브라켓트 장력보다 높을 때 까지 잡고

당깁니다. 윗실은 당겨져 나오지 않아야 됩니다.

2. 윗실을 실장력 스프링①이 실가이드③와 같은 위치가 되게 아래

로 당깁니다. 그리고 위실 장력 스프링의 장력을 측정합니다.

3. 드라이버를 실 장력 나사⑥의 홈에 넣고 돌려 실 장력 스프링의

장력을 조정합니다.

※

장력게이지⑦(별도 구매)를 사용하여 장력을 측정 시, 반드시

붉은색의 치수를 읽으시기 바랍니다.

■

Thread ten si on spri ng ten si on

1. Push the needle thread with your finger until it is slightly

highter than the thread tension bracket⑤ and so that the

upper thread is not pulled out.

2. Pull the upper thread down until the thread tension spring① is

at the same height as the base of the thread guide③, and

then measure the tension of the thread tension spring①.

3. Insert a screwdriver into the slot of the thread tension stud⑥,

and urn the screwdriver to adjust the tension of the thread

tension spring.

※

If using a tension gauge⑦ (sold separately) measure the

tension, take the reading from the scale on the side of the

red line.

10-2. 실 가이드 조정법 / A djus ting arm thread guide R

☞

ARM 실가이드 R①의 표준 위치는 나사②를 풀고 적당한

중간 위치에서 실 가이드를① 조절 하시면 됩니다.

※

조절하기 위해서는 나사②를 풀고 실가이드R의 위치를 이동

하십시오.

1. 후물 재봉 시, 실가이드R을 왼쪽으로 이동하십시오.

(천평의 운동양이 커지기 때문)

2. 박물 재봉 시, 실가이드R을 오른쪽으로 이동하십시오.

(천평의 운동양이 작아지기 때문)

☞

The standard position of arm thread guide R① is the

position where the screw② is in the center of the

adjustable range for arm thread guide R①.

※

To adjust the position, loosen the screw② and then move

arm thread guide R①.

1. When sewing thick material, move arm thread guide R① to the left.

(The thread take-up amount will become greater)

2. When sewing thin material, move arm thread guide R① to the right.

(The thread take-up amount will become less)

All manuals and user guides at all-guides.com

Summary of Contents for DB2-H515

Page 2: ...All manuals and user guides at all guides com...

Page 4: ...5 off A S 31 2 40 25 OFF A S A S All manuals and user guides at all guides com...

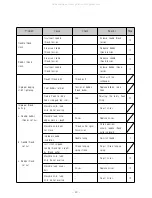

Page 34: ...24 7 7 20 20 20 10 9 7 7 12 12 16 23 All manuals and user guides at all guides com...

Page 38: ...28 12 12 12 12 puff 20 7 15 15 15 All manuals and user guides at all guides com...

Page 40: ...30 13 1 13 All manuals and user guides at all guides com...

Page 42: ...32 All manuals and user guides at all guides com...