- 20 -

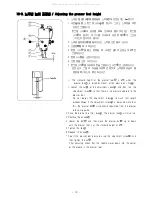

10-6. 침봉 높이 조정법 / A djus ting the need le bar heig ht

☞

침봉①이 가장 낮은 곳에 위치할 때 2번째 기선

ⓐ

이 침봉 부싱

②의 밑면모서리

Ⓐ

와 일치해야 합니다.

1. 풀리를 침봉①이 가장 낮은 곳에 위치하도록 돌립니다.

2. 오일 캡③을 제거합니다.

3. 나사④를 풀고 침봉

ⓛ

을 아래위로 움직여 위치를 조정합니다.

4. 나사④를 고정 시킵니다.

5. 오일 캡③을 닫습니다.

☞

When the needle bar① is at its lowest position, the second

reference ine

ⓐ

from the bottom of the needle bar① should

be aligned with the bottom edge

Ⓐ

of needle bar bush②.

1. Turn the machine pullry to set the needle bar① to its lowest

position.

2. Remove the oil cap.

3. Loosen the screw④ and then move the needle bar① up or

down to adjust its position.

4. Securely tighten the screw④.

5. Replace the oil cap③.

10-7. 바늘 및 가 마 타이밍 조정법 / Adjusting the needle and rotary hook timing

☞

회전가마③의 끝부분과 바늘④의 중심은 침봉①이 가장 낮은

위치에서 가장 아래의 기선

ⓐ

까지 올라갈 때 같은 선상에

있어야 합니다. 이때 기선

Ⓑ

는 침봉 부시의 밑면 모서리

Ⓐ

와

같은 선상에 있어야 합니다.

1. 땀수 조절 다이얼을 최소땀수로 맞추어 놓습니다.

2. 풀리를 침봉①이 가장 낮은 위치에서 기선

ⓐ

의 침봉 부싱②의

밑면 모서리

Ⓐ

와 같은 선상에 위치할 때까지 돌려 맞춥니다.

(바늘의 실구멍과 회전가마의 갈고리 끝은 약 0-0.5간격을 유지시킵니다.)

3. 나사⑤를 풀고 회전 가마③와 바늘의 중앙④을 일치 시킵니다.

※

회전 가마의 갈고리③ 끝부분과 바늘④의 간격공차는 0.05에서

그 이하를 유지해야 합니다.

4. 나사⑤을 고정 시킵니다.

☞

The tip of the rotary hook③ should be aligned with the

center of the needle④ when the needle bar① is raised

from its lowest position until the lowest reference line

ⓐ

from the bottom of the needle bar① is aligned with the

bottom edge

Ⓐ

of needle bar bush② as shown in the illustration.

1. Set the feed adjustment dial to the minimum setting.

2. Turn the machine pulley to raise the needle bar① from its lowest position until the lowest reference line

ⓐ

from the

bottom of the needle bar① is aligned with the bottom edge

Ⓐ

of needle bar bush② as shown in the illustration.

(The distance from the thread hole in the needle④ to the tip of the rotary hook③ will be 0-0.5㎜)

3. Loosen the three set screw⑤ and then align the tip of the rotary hook③ with the center of the needle④.

※

Set so that the clearance between the tip of the rotary hook③ and the needle④ is 0.05㎜ or less.

4. Securely tighten the three set screws⑤.

All manuals and user guides at all-guides.com

Summary of Contents for DB2-H515

Page 2: ...All manuals and user guides at all guides com...

Page 4: ...5 off A S 31 2 40 25 OFF A S A S All manuals and user guides at all guides com...

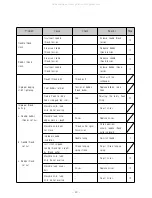

Page 34: ...24 7 7 20 20 20 10 9 7 7 12 12 16 23 All manuals and user guides at all guides com...

Page 38: ...28 12 12 12 12 puff 20 7 15 15 15 All manuals and user guides at all guides com...

Page 40: ...30 13 1 13 All manuals and user guides at all guides com...

Page 42: ...32 All manuals and user guides at all guides com...