www.ultratecfx.com

7

Operation Procedure

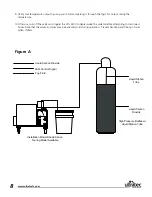

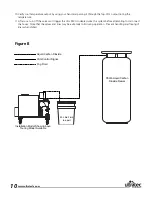

LSG MK II High Pressure w/ 20 & 50lbs Cylinders

The Operation Procedures outlined in this section, refer to Figure A Page 9.

1. Place the fog machine’s output nozzle firmly against the center of the foam ring, sealing it to the input port of the

LSG MK II.

Tech Tip:

Proper alignment can be observed by shining a flashlight into the 10” exit port of the LSG MK II and noting

the fogger’s output nozzle is centered on the LSG MK II input port.

2. Connect the grey Twist Lock connector from the LSG MK II into the controlling power source (i.e. control port on

the rear panel of the Power Fog Family of Ultratec Special Effects Foggers). This port can be controlled via DMX, the

Timer/ Duration Remote or the Show Control Remote.

Note:

Starting the flow of CO2 before the fog allows the liquid CO2 to purge the gas CO2 from the lines. The Liquid

CO2 is required for correct operation. The rule of thumb formula for calculating the purge time is 1 second for every 3

feet of hose. As the unused liquid sits in the hose, it absorbs heat and converts to its gaseous state.

3. Use Molecular Fog Fluid and adjust the flow rate to the desired fog output level. Excessive fog flow will not cool

sufficiently allowing the fog to rise off of the floor.

Warning:

Always secure all cylinders to prevent tipping hazards.

4. An LSG MK II High Pressure requires high pressure CO2 cylinders. These are normally available in 20 & 50lb sizes. It

is recommended that cylinders equipped with liquid siphon tubes be used.

5. The CO2 supply hose is connected to the CO2 cylinder. Exercise safe handling and connection of the tank as

indicated by the gas supplier. A sealing washer is necessary to prevent leaks between the hose and valve and is

available from your gas supplier.

6. Tighten the CO2 hose-fitting snug with the appropriate wrench.

Warning:

Wear eye protection and gloves to protect against cold and pressure hazards

7. Open valve slowly counter-clockwise until flow can be heard. Verify the lines have no leaks before opening the valve

fully.

8. When the fog machine is up to operating temperature, activate the control to start the CO2 for the desired purge

and pre-chill time. Purging of the CO2 gas can be noted by the change in the sound of flow. It is often desirable to

pre-chill the chamber and long runs of ductwork like a Fog Curtain. Now add fog to create the thick, white rolling

blanket that hugs the floor. On the Power Fog Family of Ultratec Special Effects Foggers, the CO2 is triggered by

DMX (DMX c 1) or by one of the remotes. To control using the remote, the DMX address is selected as 555.

This allows the Duration knob (turned up over 1/2 way) of the Timer/ Duration Remote or the second channel of the

Show Control Remote to trigger the LSG MK II.