CF.440.400.001.IM.0417

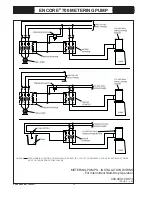

ENCORE

®

700 METERING PUMP

13

CHEMICAL COMPATIBILITY OF METERING PUMPS - PERFORMANCE

440.050.190.010F

ISSUE 0 8-95

1. WARNING: DRIED RESIDUE OF SPILLED

SOLUTIONS IS EXPLOSIVE.

3. SS TO180°F

5. PVC TO 125°F

6. HYPALON TO 180°F

7. SS TO 125°F 10%, PVC TO 125°F

8. PVC TO 125°F, 29%, SS TO 180°F, 29%

9. SS TO 70°F, 5%

10. PVC TO 105°F, 40%, SS TO 180°F SAT

11. VITON TO 180°F

12. PVC TO 100°F PURE

13. VITON TO 158°F

14. SS TO 140°F

15. USE SLURRY VALVES

16. PVC TO 105°F, SS TO 180°F

17. PVC TO 100°F, SS TO 100°F

18. SS TO 70°F DILUTE, PVC TO 125°F

19. PVC TO 100°F, 50%, SS TO 70°F, 5%

20. PVC TO 100°F, 25%, SS TO 180°F, 50%

21. PVC TO 100°F, SS TO 160°F

22. VITON TO 120°F

24. PVC TO 125°F, 36%, SS TO 180°F 10%

25. FLUORIDATION REQUIRES AN ANTI-

SYPHON PUMP INSTALLATION CONSULT

LOCAL REGULATIONS FOR DETAILS.

26. PVC TO 30%

27. PVC TO 125°F, 50%, SS TO 70°F, 5%

28. MAY CAUSE SURFACE PITTING TO SS

29. PVC TO 125°F, 48%

30. HYPALON TO 130°F

31. PVC TO 100°F, 50%, SS TO 100°F, 50%

32. PVC TO 70°F, 10%, SS TO 70°F, 10%

34. SS TO 70°F, 5%, PVC 125°F SAT

35. PVC TO 100°F, SS TO 70°F

36. VITON TO 100°F

37. HYPALON TO 150°F

38. SS TO 70°F, 10%

39. PVC TO 125°F, 80%, SS TO 70°F, 80%

40. PVC TO 100°F, SAT, SS TO 180°F, 50%

41. SS TO 180°F, 5%

42. PVC TO 70°F, 50% OR TO 125°F, 30%, SS

TO 180°F, 50%

43. SS TO 140°F, 10%

44. SS TO 180°F, 50%

45. PVC TO 105°F

46. PVC TO 125°F, 4%, SS TO 70°F, 5%

47. PVC TO 125°F, 15%, SS TO 70°F, 5%

48. SS TO 125°F

49. PVC TO 125°F, 41 Be, SS TO 140°F, 41 Be

50. PVC TO 125°F, 30%

51. PVC TO 125°F, 50%, SS TO 70°F, 50%

52. PVC TO 100°F, 10%, SS TO 150°F

53. PVC TO 100°F, SS TO 180°F, 70%

57. KYNAR TO 70°F

58. KYNAR TO 120°F

59. KYNAR TO 120°F, 30%

60. KYNAR TO 100°F

Statements and suggestions set forth herein are based upon the best information and practices known to UGSI Chemi-

cal Feed, Inc. However, it should not be assumed either that information is complete on the subjects covered or that

all possible circumstances, safety measures, precautions, etc., have been included. These statements and suggestions

are not intended to refl ect state, municipal, or insurance requirements or national safety codes; where applicable, those

sources should be consulted directly. Moreover, since the conditions of use are beyond its control, UGSI Chemical

Feed, Inc. makes no guarantee of results and assumes no liability in connection with the information contained herein.

When dealing with the installation, operation or maintenance of a specifi c UGSI Chemical Feed, Inc. product, the

manuals and data sheets pertaining to that product should be studied carefully. In case of any doubt about a specifi c

installation, direct inquiries to your local UGSI Chemical Feed, Inc. representative.

Summary of Contents for Encore 700

Page 2: ......

Page 3: ...ENCORE 700 DIAPHRAGM METERING PUMP MANUAL NO CF 440 400 001 IM 0417...

Page 6: ......

Page 8: ......

Page 16: ...CF 440 400 001 IM 0417 ENCORE 700 METERING PUMP...

Page 30: ...CF 440 400 001 IM 0417 ENCORE 700 METERING PUMP 14...

Page 70: ......

Page 124: ...CF 440 400 001 IM 0417 ENCORE 700 METERING PUMP 107...