CF.440.400.001.IM.0417

ENCORE

®

700 METERING PUMP

34

4.3.1

Gearbox Lubrication (Refer to Dwg. 440.400.000.010)

The gearbox is fi lled with approximately two quarts of Bel-Ray Worm Gear Oil

460, (Product Code 11000). This lubricant must be replaced annually to realize

optimum performance of the mechanism. The fi rst oil change is

recommended after six months of operation.

NOTE: Do not mix oils.

To drain and replace the gearbox oil, perform the following steps:

a. Remove the oil drain plug (33) located at the bottom of the side wall of the

gearbox (toward the stroke control knob). Catch the oil with an appropriate

container.

b. Let the oil drain completely and fl ush the gearbox using suitable detergents.

c. Apply PTFE tape to the oil drain plug and install it to the gearbox.

d. Remove the breather cap (44) located at the top of the gearbox cover and

the oil check plug (36) located at the center of the gearbox side wall (toward

the stroke control knob)

e. Fill the gearbox with oil (U40003) until the oil fl ows out of the oil check

hole.

f. Apply PTFE tape to the oil check plug; thread and tighten.

g. Install the breather cap.

4.3.2

Priming Troubles or Loss of Suction

Diffi

culties in priming are usually encountered when there is an air leak in the

suction line or when the valves are obstructed. Air leaks in the suction line may

be due to a loose valve, O-ring damage, cracked tubing, or leaking joints in the

pipe thread connections. Obstruction on the valves may be caused by foreign

material or by deposits on the pumping head parts.

Where liquid is withdrawn from containers that are replaced when they are

empty, or if the level in a fi xed tank occasionally falls below the suction line

inlet, air will be introduced into the pump. If the pump is discharging against

atmospheric pressure (or only slightly above), the pump may be expected to

re-prime itself if the liquid supply is replenished and it is operated briefl y at

full stroke. If discharging against greater pressures, the pump will not re-prime

itself due to compression and re-expansion of the air trapped in the pump head.

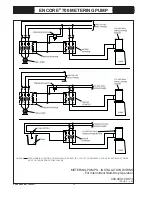

If the system is installed in accordance with Dwgs. 440.400.110.030 or

Summary of Contents for Encore 700

Page 2: ......

Page 3: ...ENCORE 700 DIAPHRAGM METERING PUMP MANUAL NO CF 440 400 001 IM 0417...

Page 6: ......

Page 8: ......

Page 16: ...CF 440 400 001 IM 0417 ENCORE 700 METERING PUMP...

Page 30: ...CF 440 400 001 IM 0417 ENCORE 700 METERING PUMP 14...

Page 70: ......

Page 124: ...CF 440 400 001 IM 0417 ENCORE 700 METERING PUMP 107...