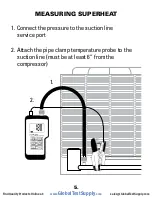

What is Super Heat / Sub Cool?

Refrigerant

superheat

refers to the rise in

temperature of vapor after the refrigerant has com-

pletely changed from a liquid to a gas. The dew point

(temperature at measured pressure where all of the

liquid evaporates) is determined by properties of the

refrigerant and measuring the pressure. When com-

paring this to the measured pipe temperature of the

return line will determine superheat. The SSM1 will

calculate this value directly and update in real time.

Use superheat on fixed orifice or capillary systems.

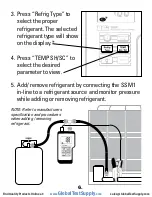

Refrigerant

subcooling

refers to the drop in

temperature of liquid refrigerant after it has com-

pletely changed from a gas to a liquid. The boiling

point (temperature at measured pressure where the

liquid stops boiling and starts to further cool) is deter-

mined by properties of the refrigerant and measuring

pressure. When comparing this to the measured pipe

temperature at the exit of the condenser determines

subcooling. The SSM1 will calculate this value

directly, and update in real time. Use Subcooling

on TXV systems, as they are designed to maintain a

constant superheat.

2.

www.

GlobalTestSupply

.com

Find Quality Products Online at: