v

erify

p

roper

o

peratioN

o

f

C

ombuStioN

e

quipmeNt

• To verify that equipment is operating as the manufacturer designed it to work.

This includes installation tests for CO2 and CO.

- A properly tuned combustion appliance will perform better, and reduce the likelihood of

call-backs for no-heat.

• To verify that the maintenance work performed has corrected the problem.

• To detect any defects early – possibly at installation.

- Higher efficiency equipment is running at peak only when properly adjusted. As the complexity

of a system increases, so does the importance of proper adjustment of the combustion process.

• Improperly adjusted equipment not only fails to meet expected performance but could lead to future

failures.

• To check that the equipment is supplied with enough combustion air, make-up air and has proper

venting to exhaust the combustion by-products.

• To establish a base-line of desired performance -

- By tracking the performance over time you are able to see changes before they lead to equipment

failure.

v

erify

S

afe

o

peratioN

o

f

C

ombuStioN

e

quipmeNt

• Equipment that is not properly adjusted, or that has insufficient draft to vent combustion gases could

produce carbon monoxide in deadly quantities. The UEi C20 can be used to test both flue gas and

ambient CO.

• When customers complain about fumes it is usually an indication of improper operation. CO is a

colorless, odorless gas so the fumes are not the CO, but an indication that a problem may exist.

i

mprove

y

our

p

roduCtivity

& p

rofit

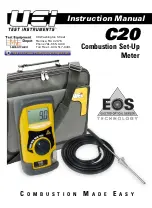

• The UEi

C20

combustion set-up meter gives a quick, continuous readout of the combustion process.

Readings change in real-time as adjustments are made to help zero in on the proper setting.

Compare this to spot tests or other methods, and you will see your productivity rise.

• Proper testing will help you provide the proper service or equipment replacement recommendations,

and have the data to support this. Sales will increase because you are no longer guessing, and the

work provided is proper for the needs of the customer.

• Customers on a service contract will be provided excellent service, and you will quickly diagnose

failures and help keep the equipment up for the season.

i

mprove

C

uStomer

p

erCeptioN

o

f

y

our

S

erviCeS

• Provide your customers results of the performance of their equipment

• Reduce your customers energy expense by properly adjusting and maintaining their equipment

• Increase your confidence in the work performed and remember

i

f

y

ou

d

oN

’

t

t

eSt

, y

ou

d

oN

’

t

K

Now

WHY TEST WITH

THE C20

5