reV: 17f

SMoGHoG

®

SHM Series Models

13

3.7 DRAINS

All SHM units are supplied with 1-1⁄2˝ FNPT drain

connections. a drain trap or similar is to be utilized to

prevent air from being sucked up through the drain when

unit is running.

NOTES:

Main drain line should be sufficiently sloped and

vented. all plumbing should conform with all

state and local codes.

appropriate design criteria as provided by a plumbing/

mechanical contractor should be utilized to ensure

proper control of drainage from the SHM unit.

4. UNIT OPERATION

4.1 START-UP

Before system start-up, verify that the installation is

complete per Section 3 of this manual. the following

are the basic steps to walk you through as you are

starting up.

1. open the SHM filter access doors and verify that the

filters are in place and properly sealed.

2. ensure that all circuit breakers are switched on.

3. ensure that the main power is connected and

turned on.

4. close and latch all access doors and electrical

enclosures on the unit.

5. Blower rotation should be checked on all Basic units.

the blower should be turning counterclockwise when

viewed from above.

6. on advanced units follow Section 4.3 for setting changes

on the touchscreen to target the desired airflow volume.

adjust the blower speed to the rPM % that will provide the

targeted airflow. for assistance in determining the target

rPM, contact your local representative. When using

the auto flow option, follow the auto flow Settings in

Section 4.3.4 refer to figure 19.

7. Press the blower power button on the Home screen

to begin operation on advanced units. note that if

the oil mist collector is connected to a process, other

equipment will need to be engaged as well. on basic

units the motor starter switch or disconnect should be

switched on.

8. Verify performance of the system by measuring

airflow or evaluating capture at each collection point.

it is recommended to record baseline performance

parameters so the system can be reset in case of an

upset condition or system change. the recorded data

should include:

• the static pressure at each collection hood

• system amperage draw and filter pressure drop at a

minimum

• any other key pieces of data critical to your process.

9. To optimize system performance and extend filter life,

run the unit at the minimum airflow required to control

the process.

4.2 SYSTEM OPERATION

as the SHM collects contaminate, a layer builds up on

the outside surface, causing an increased pressure drop

through the filters. as the differential pressure rises,

the blower rPM will need to be increased in order to

maintain the desired airflow (when equipped). a damper

is to be used to control flow on all basic SHM units to be

supplied by the customer. When the filters are saturated,

the contaminant drips to the bottom of the unit and

collects within the oil sump where it can be drained and

disposed of. When the system can no longer generate

the airflow required to capture or convey the collected

contaminate, the filters must be replaced.

4.2.1 ADVANCED UNIT OPERATION

4.2.1.1 AIRFLOW ADJUSTMENT USING

MANUAL SPEED CONTROL

the advanced SHM features an electronically

commutated (ec) blower that is equipped with airflow

adjustment using the blower rPM. to adjust the airflow,

the blower speed (rPM) percentage can be adjusted from

20 to 100%. as filter pressure builds, it may be necessary

to increase the rPM to maintain proper capture and

transport velocity within the hood and duct system.

the adjustment of the rPM is done in the Blower display

screen, see figure 9.

4.2.1.2 AIRFLOW ADJUSTMENT USING

AUTO-FLOW CONTROL

With the auto-flow feature, the SHM will automatically

adjust the rPM of the blower to maintain the airflow set-

point. refer to figures 11 & 19. When the system can no

longer maintain airflow, a warning will be provided on

the touchscreen. in the event of a warning or failure on

the touchscreen, refer to the troubleshooting section of

this manual to help determine the cause and associated

solution.

CAUTION

Summary of Contents for SMOGHOG SHM-05C

Page 1: ...Model SHM 05C Shown SMOGHOG Media Mist Collector l Models SHM 05C SHM 08C OWNER S MANUAL ...

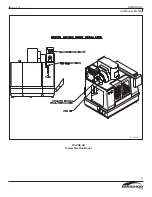

Page 11: ...REV 17F SMOGHOG SHM Series Models 7 FIGURE 3B Typical Machine Mount 61 10144 ...

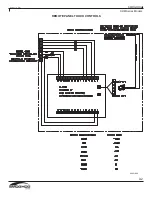

Page 14: ...REV 17F SMOGHOG SHM Series Models 10 61 10129 Figure 4 Remote Panel Touchscreen Connection ...

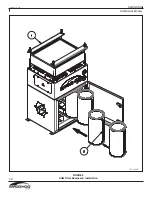

Page 16: ...REV 17F SMOGHOG SHM Series Models 12 61 10133 Figure 5 SHM Filter Removal Installation ...

Page 26: ...REV 17F SMOGHOG SHM Series Models 22 61 10134 Figure 22 ...

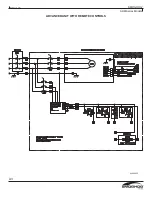

Page 27: ...REV 17F SMOGHOG SHM Series Models 23 A1 BASIC UNIT 04 001990 ...

Page 28: ...REV 17F SMOGHOG SHM Series Models 24 A2 REMOTE PANEL TOUCH CONTROLS 04 001802 ...

Page 29: ...REV 17F SMOGHOG SHM Series Models 25 A3 ADVANCED UNIT WITH REMOTE CONTROLS 04 002235 ...

Page 30: ...REV 17F SMOGHOG SHM Series Models 26 A4 575 480 TRANSFORMER 04 001717 ...