4

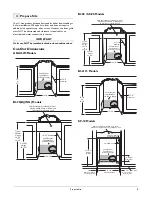

U-Line Prepare Site

SS-1095NF Models

SS-1095FC Models

SS1095FD

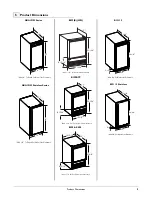

BCM95 Models

WH95TP Models

BI95BTP

8"

Typical

Counter

Height

34-1/4"

to

35-1/8"

Cut-Out

Height

25-1/16"

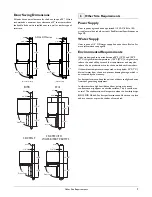

Filler Panel (Not Provided by U-Line) –

May Be Added Above or Below Unit

to Enclose for a Built-In Look

14-1/4"

18-1/2" Minimum

See Electrical

Specifications

for Power Supply

Cut-Out

Height

25-1/8”

Filler Panel (Not Provided by U-Line) –

Needed to Attach Mounting Flange on Unit

18-1/2” Minimum

See Electrical

Specifications

for Power Supply

8" Height

From Floor

14-1/4”

Cut Out Width

3/4”

Minimum Flange

Mounting Area

3/4”

Minimum Flange

Mounting Area

Cut-Out

Height

25-1/8”

Filler Panel (Not Provided by U-Line) –

Needed to Attach Mounting Flange on Unit

18-1/2”” Minimum

See Electrical

Specifications

for Power Supply

8" Height

From Floor

14-1/4”

Cut Out Width

3/4”

Minimum Flange

Mounting Area

3/4”

Minimum Flange

Mounting Area

Cut-Out

Height

26-1/16"

Filler Panel (Not Provided by U-Line) –

Needed to Attach Mounting Flange on Unit

18-1/2” Minimum

See Electrical

Specifications

for Power Supply

8" Height

From Floor

14-3/4”

Cut Out Width

3/4”

Minimum Flange

Mounting Area

3/4”

Minimum Flange

Mounting Area

Cut-Out

Height

25-1/8"

18-1/2" Minimum

See Electrical

Specifications

for Power Supply

8" Height

From Floor

Filler Panel (Not Provided by U-Line) –

Needed to Attach Mounting Flange on Unit

Toe Kick

14-1/4"

Cut-Out Width

3/4"

Minimum Flange

Mounting Area

3/4"

Minimum Flange

Mounting Area

3/4”

Minimum Flange

Mounting Area

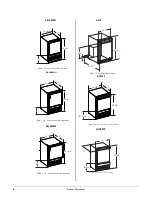

Cut-Out

Height

25-1/16"

18-1/2" Minimum

See Electrical

Specifications

for Power Supply

8" Height

From Floor

Filler Panel (Not Provided by U-Line) –

Needed to Attach Mounting Flange on Unit

Toe Kick

14-1/4"

Cut-Out Width

3/4"

Minimum Flange

Mounting Area

3/4"

Minimum Flange

Mounting Area

3/4”

Minimum Flange

Mounting Area