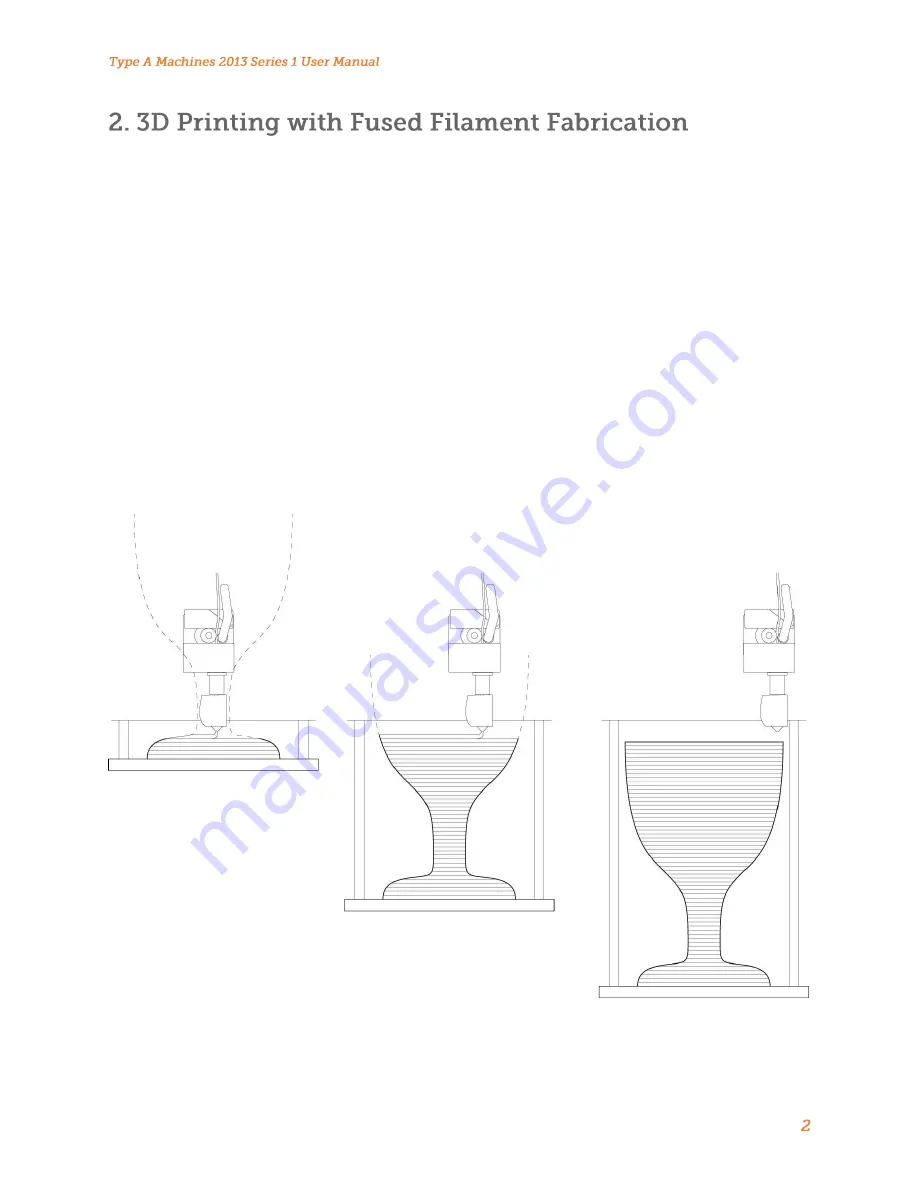

The Type A Machines Series 1 prints a 3D object by placing thin layers of plastic on top of each other until

a finished object is built out of the layered plastic.

To begin a 3D print, plastic is delivered to the Series 1 Tool Head in the form of “filament” (a long thin

strand of plastic, wound onto a spool). The Series 1 then heats the filament to its melting point and pushes,

or “extrudes,” the melted filament through the Extruder Nozzle. The Series 1 then moves the Nozzle in a

pattern while extruding plastic to draw a very thin cross section of the object that it is printing. The Tool

Head fan cools the newly extruded plastic, solidifying it almost instantly. After each layer is completed, the

printer moves the Build Surface down a tiny distance, and then extrudes the next cross section of melted

plastic on top of the cooled layer below.

This method of 3D printing is called Fused Filament Fabrication, or “FFF”.

Figure 2.0. 1