55

4. Traction devices and steering system

Trouble and possible cause

Possible remedy

A. Front wheel swing

(1) Excessive clearance of front wheel bearing or

kingpin sleeve worn out excessively

(2) Wrongly adjusted toe-in

(3) Ball pin and ball pin seat worn out excessively

(4) Pitman arm and ball pin fixing nut loose

B. Early worn out of front wheel tires

(1) Wrongly adjusted toe-in

(2) Front wheel pressure insufficient

C. Excessive steering wheel free travel

(1) Ball pin and ball pin seat won out excessively

(1) Adjust bearing clearance and replace

kingpin sleeve

(2) Readjust toe-in

(3) Replace ball pin and ball pin seat

(4) Check and tighten the nut

(1) Readjust toe-in

(2) Inflate tire to specified pressure

(1) Replace ball pin or ball pin seat

(2) Check and tighten the nut

5. Hydraulic system

Trouble and possible cause

Possible remedy

A. Lack of lifting force or lifter will not lift

(1) Low oil level or improper type of oil

(2) Clogged oil inflow trainer

(3) Air in hydraulic system

(4) Oil pump seriously worn out, leaking serious

(5) Lower valve is open

(6) Main control valve or return valve worn out

seriously

(7) Ineffective safety valve

(8) Cylinder leaking seriously

(9) Leakage at distributor seal rings

B. Implement lifted with shake

(1) Lower valve is close

(2) Closed lowering speed regulating valve or shut-

Off valve

C.Implement lifted with shake

(1) Check valve worn out and closed incompletely

(2) Leakage at seal rings of the distributor and

Cylinder

(1) Add proper oil to specified level

(2) Flush the strainer

(3) Drain system and tighten contactor or

replace seal ring

(4) Replace oil pump seal ring

(5) Dismount and clean

(6) Replace worn out parts

(7) Readjust or repair safety valve

(8) Replace seal ring or replace worn out parts

if necessary

(9) Replace seal rings

(1) Dismount and clean

(2) Open the valve

(1) Repair or replace check valve

(2) Find out the position of leakage and

replace worn out seal rings

Summary of Contents for ET350 ECONO

Page 69: ...62 8 3 Electrical system wiring diagram...

Page 73: ...66 ET 350 ECONO 4WD TRACTOR ENGINE PARTS CATALOGUE...

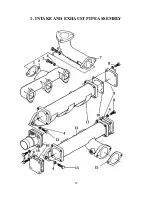

Page 74: ...67 1 INTAKE AND EXHAUST PIPE ASSEMBLY...

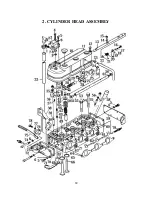

Page 76: ...69 2 CYLINDER HEAD ASSEMBLY...

Page 80: ...73 3 CYLINDER BLOCK ASSEMBLY...

Page 84: ...77 4 CAMSHAFT ASSEMBLY...

Page 86: ...79 5 CRANKSHAFT FLYWHEELASSEMBLY...

Page 88: ...81 6 PISTON CONNECTING ROD ASSEMBLY...

Page 90: ...83 7 FUEL SYSTEM ASSEMBLY...

Page 92: ...85 8 COOLING SYSTEM...

Page 95: ...88 9 LUBRICATION SYSTEM ASSY...

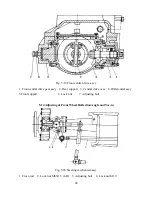

Page 97: ...90...

Page 98: ...91 Electric EGR Illustration Diagram...

Page 100: ...93 ET 350 ECONO 4WD TRACTOR Chassis PARTS CATALOGUE...

Page 102: ...95 1 DRY AIR FILTER...

Page 104: ...97 2 ENGINE CONTROL MECHANISM ASSY...

Page 107: ...100 3 CLUTCH...

Page 110: ...103 4 INTERMEDIATE HOSE ASSY...

Page 113: ...106 5 TRANSMISSION HOUSING...

Page 116: ...6 PRIMARY SHAFT 109...

Page 118: ...7 MAIN SHAFT 111...

Page 120: ...8 TRANSMISSION COVER ASSY 113...

Page 122: ...9 DIFFERENTIAL 115...

Page 124: ...10 PTO SHAFT ASSY 117...

Page 126: ...11 BRAKE ASSY 119...

Page 129: ...122 12 REAR DRIVING WHEEL ASSY...

Page 131: ...124 13 FINAL DRIVE ASSY...

Page 134: ...14 FUEL TANK BRACKET 127...

Page 136: ...15 SUSPENSION LINKAGE ASSY 129...

Page 139: ...16 FRONT DRIVING AXLE ASSY A 132...

Page 142: ...17 FRONT DRIVING AXLE ASSY B 135...

Page 145: ...138 18 FRONT DRIVING AXLE ASSY C...

Page 147: ...140 19 FRONT DRIVING AXLE ASSY D...

Page 150: ...143 20 FRONT DRIVING WHEELASSY...

Page 152: ...145 21 STEERING MECHANISM...

Page 154: ...147 22 TRANSFER CASE ASSY...

Page 157: ...150 23 HYDRAULIC POWER LIFT...

Page 160: ...153 24 POWER LIFT CONTROL MECHANISM...

Page 163: ...156 25 CYLINDER DISTRIBUTOR ASSY...

Page 166: ...159 26 FENDER FLOOR BOARD TOOL BOX...

Page 168: ...161 27 BONNET 1...

Page 171: ...164 28 BONNET 2...

Page 173: ...166 29 SIDE COVER...

Page 175: ...ET350 ECONO OPERATOR S MANUAL FOR TRACTORS CODE NO Printed on June 2006 2 nd EDITION...