37

In case of abnormal teeth contact condition, it is possible to make adjustments according to Fig. 5-4.

The solid line with arrow head shows the adjustment of teeth contact, while the dashed line shows the

adjustment of backlash.

(4) When it is assured of normal teeth contact condition, the backlash could be adjusted to 0.1~0.2 mm.

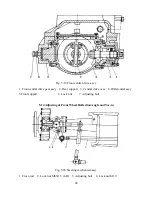

5.4 Adjustment of Brakes

The adjustment of the brakes is shown in Fig. 5-5. The length of the control rod is adjusted so that

when the top of the brake pedal is subjected to a force of 13 N. the travel should be 20~40 mm.

It shall be assured also that the left and right brakes will work equally effectively.

Fig. 5-5 Adjustment of brakes

1. Brake pedal

2. Control rod

3. Lock nut

4. Adjusting fork

5. Rocker arm of cam

5.5 Adjustment of Final Drive

For adjustment of preloading of the drive shaft bearings, see Fig. 5-6

(1) Place of piece of fuse wire of about 2mm diameter between the inner bearing cover and the bearing

No.7307. Place also a set of adjusting shims of a total thickness of about 1.5 mm. After mounting the

inner bearing cover, tighten the bolts with a torque of 40~50 N*m, to press the fuse into a flat plate.

(2) Dismount the bearing cover, take out the fuse plate and measure its thickness.

(3) Deduct the thickness of the fuse plate from the total thickness of the shims. This will form a set

of shims, the use of which will result in clearance or interference of less than 0.1 mm. Assemble the

shims and bearing cover and tighten the bolts with a torque of 40~50 N*m.

Summary of Contents for ET350 ECONO

Page 69: ...62 8 3 Electrical system wiring diagram...

Page 73: ...66 ET 350 ECONO 4WD TRACTOR ENGINE PARTS CATALOGUE...

Page 74: ...67 1 INTAKE AND EXHAUST PIPE ASSEMBLY...

Page 76: ...69 2 CYLINDER HEAD ASSEMBLY...

Page 80: ...73 3 CYLINDER BLOCK ASSEMBLY...

Page 84: ...77 4 CAMSHAFT ASSEMBLY...

Page 86: ...79 5 CRANKSHAFT FLYWHEELASSEMBLY...

Page 88: ...81 6 PISTON CONNECTING ROD ASSEMBLY...

Page 90: ...83 7 FUEL SYSTEM ASSEMBLY...

Page 92: ...85 8 COOLING SYSTEM...

Page 95: ...88 9 LUBRICATION SYSTEM ASSY...

Page 97: ...90...

Page 98: ...91 Electric EGR Illustration Diagram...

Page 100: ...93 ET 350 ECONO 4WD TRACTOR Chassis PARTS CATALOGUE...

Page 102: ...95 1 DRY AIR FILTER...

Page 104: ...97 2 ENGINE CONTROL MECHANISM ASSY...

Page 107: ...100 3 CLUTCH...

Page 110: ...103 4 INTERMEDIATE HOSE ASSY...

Page 113: ...106 5 TRANSMISSION HOUSING...

Page 116: ...6 PRIMARY SHAFT 109...

Page 118: ...7 MAIN SHAFT 111...

Page 120: ...8 TRANSMISSION COVER ASSY 113...

Page 122: ...9 DIFFERENTIAL 115...

Page 124: ...10 PTO SHAFT ASSY 117...

Page 126: ...11 BRAKE ASSY 119...

Page 129: ...122 12 REAR DRIVING WHEEL ASSY...

Page 131: ...124 13 FINAL DRIVE ASSY...

Page 134: ...14 FUEL TANK BRACKET 127...

Page 136: ...15 SUSPENSION LINKAGE ASSY 129...

Page 139: ...16 FRONT DRIVING AXLE ASSY A 132...

Page 142: ...17 FRONT DRIVING AXLE ASSY B 135...

Page 145: ...138 18 FRONT DRIVING AXLE ASSY C...

Page 147: ...140 19 FRONT DRIVING AXLE ASSY D...

Page 150: ...143 20 FRONT DRIVING WHEELASSY...

Page 152: ...145 21 STEERING MECHANISM...

Page 154: ...147 22 TRANSFER CASE ASSY...

Page 157: ...150 23 HYDRAULIC POWER LIFT...

Page 160: ...153 24 POWER LIFT CONTROL MECHANISM...

Page 163: ...156 25 CYLINDER DISTRIBUTOR ASSY...

Page 166: ...159 26 FENDER FLOOR BOARD TOOL BOX...

Page 168: ...161 27 BONNET 1...

Page 171: ...164 28 BONNET 2...

Page 173: ...166 29 SIDE COVER...

Page 175: ...ET350 ECONO OPERATOR S MANUAL FOR TRACTORS CODE NO Printed on June 2006 2 nd EDITION...