3: TX CALIBRATION

Submenu Configuration Steps

Ensure all controls are working correctly. In the primary setting mode, apply positive collective pitch. Check whether the

directions of swash plate servos (AILERON, ELEVATOR and PITCH) are correct. If incorrect, the AILERON,

ELEVATOR and PITCH servo direction can be changed via your transmitter – servo reverse. This step needs to be

completed before continuing on.

SWPL TRIM CALIBR - Swash plate Level Calibration at Middle (Mid stick point)

Ensure the unit is in Primary setup mode

Place the collective pitch stick to the exact middle point (Mid stick). Ensure the swash plate is level. This can be changed

mechanically via the swash links or by adjusting the Sub-trim within your transmitter.

Once level, activate the

SWPL TRIM CALIBR

calibration by pressing the appropriate button on the LCD programmer.

The LCD Programmer will display „Calibration OK” once complete.

After this task has completed, any previous AUTOTRIM data in the memory will be deleted.

Return the unit the to normal flying mode.

SWPL LOW CALIBR - Swash plate Low Level Calibration

With the collective pitch stick is at the low end adjust the low end travel of the AILERON, ELEVATOR and PITCH

servos via your transmitter (ATV settings) to set the desired position.

Press the appropriate button on the LCD programmer to activate the calibration.

The LCD Programmer will display „Calibration OK” once complete.

SWPL HIGH CALIBR - Swash plate High Level Calibration

With the collective pitch stick is at the high end adjust the high end travel of the AILERON, ELEVATOR and PITCH

servos via your transmitter (ATV settings) to set the desired position.

Press the appropriate button on the LCD programmer to activate the calibration.

The LCD Programmer will display „Calibration OK” once complete.

4: SENSOR SETTINGS

Submenu Configuration Steps

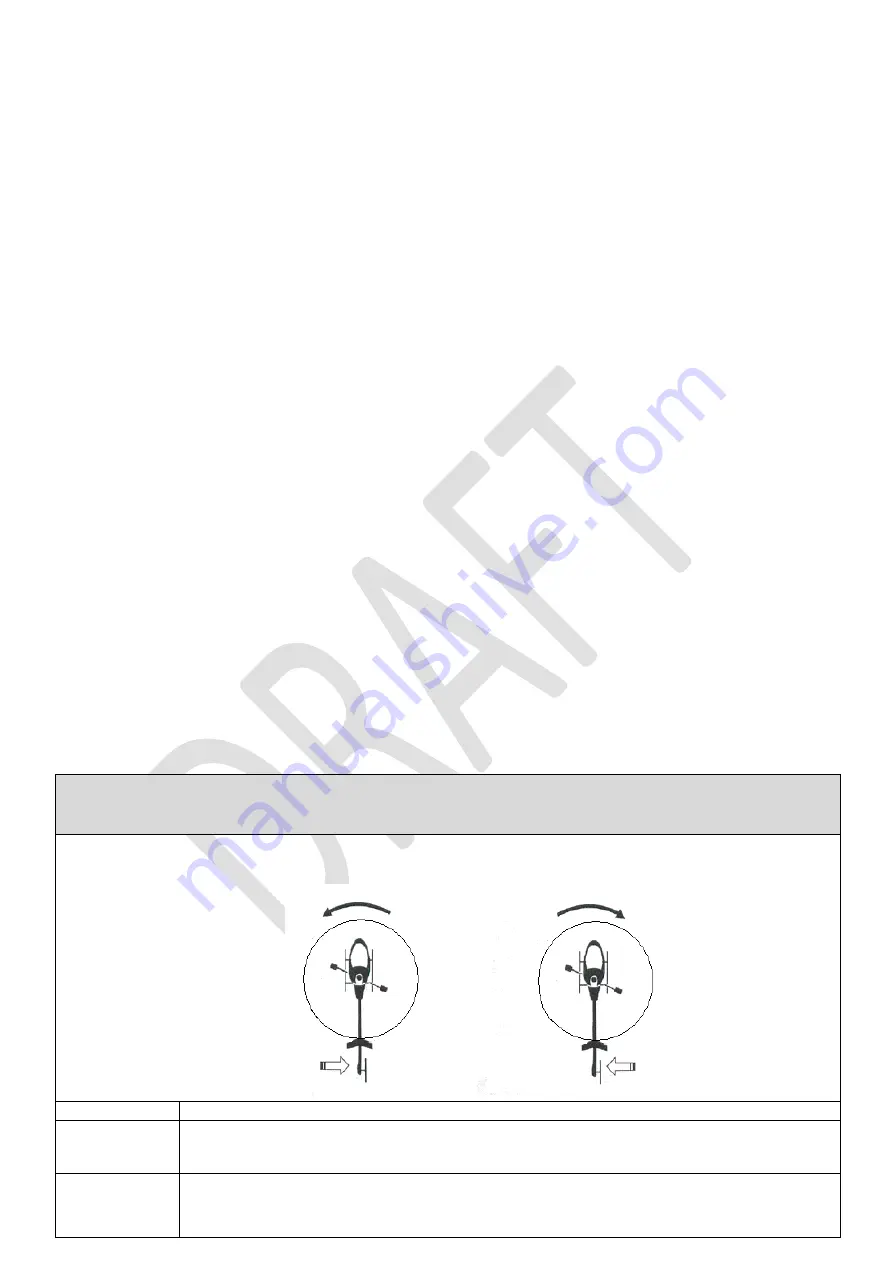

RUD-DIRE - Rudder gyro direction selection

Attention: Check that the rudder direction matches the transmitter stick direction. Otherwise, please reverse the rubber

direction via your transmitter.

Menu items

Description

NORM

(Default)

Rotate the helicopter left (nose). Rudder servo should compensate to the right automatically.

Otherwise, change value to “REV”.

As shown in the diagram.

REV

Rotate the helicopter left (nose). Rudder servo should compensate to the right automatically.

Otherwise, change value to “NORM”. As shown in the diagram.

Direction of resulting yaw

Direction of resulting yaw

Tail rotor thrust

Tail rotor thrust