9

CAUTION!

Do not apply excessive force to the manual override, doing

so will damage the product and effect the performance.

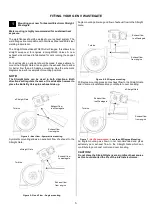

Using your ECU manager software, read the voltage from the

sensor and set this as your closed position.

Wind the manual adjustment in an anticlockwise direction until it

stops. From this position rotate the adjustment 2 full turns in a

clockwise direction. Read the sensor value and set this as 100%

butterfly valve travel.

Monitor sensor signal voltage to ensure no wrap around occurs

throughout the stroke of the butterfly valve that could affect

operation.

CAUTION!

It is critical not to set the 100% position at the end of the

travel as this may lead to seizing of the wastegate and

overloading the system.

NOTE!

Turbosmart recommends allowing additional clearance

from the end stops until the wastegate control is tuned to

minimise risk of overshoot into end stops at high speeds.

Tuning

The eWastegate will come calibrated from Turbosmart, the

targeted values have been set with regards to the position sensor

are approx. 0.5V (completely open) and approx. 4.5V as

(completely closed), It is important to note that as the wastegate

butterfly valve moves through its range of motion that the butterfly

valves are monitored to move from 4.5V decreasing to 0.5V, 0%

open to 100% open. This should be done manually with the ECU

package monitoring Voltage Values. The electronic motor should

be disconnected at this point.

Voltage wraps around will cause errors with the eWastegate, this

is when the Voltage increases from 4.8V up to 5V and jumps

through to 0V.

Position Sensor

Target Voltage (V)

Duty Cycle

100% (Open)

0.20-0.60V

~16%

0% (Closed)

4.40-4.80V

~84%

It is important to set up the correct limits manually with

eWastegate. Turbosmart recommends that the butterfly valve is

only ever driven electronically to the maximum butterfly position

of 90

%.

Driving the butterfly valve to 100% will cause increased

wear on components such as the electronic motor as it

tries to force the butterfly valve to completely open.

Adjust the calibration to allow plenty of overshoot to the end stops

of the butterfly valve, recalibrate as above once you have good

control of butterfly position.

PLEASE NOTE

that temperatures over 180 degC (356degF)

will create an error in the temperature sensor readings.

Therefore, the internal temperature is rated to a temperature of

150degC (302degF) it is recommended to log and place

sufficient alarms to monitor this.

PLEASE NOTE

When driving the electronic actuator, the current

should be limit to

no more

than 20 amps at a period of 1 second

and 5 amps for more than 5 seconds.

Follow your ECU manufacturers guidelines for tuning wastegate

servo control. Ensure dead band is set to a reasonable level to

not have the output active when not needed.

Sensor Linearisation

Due to the nature of the butterfly valve design, the flow

characteristics are nonlinear. In some cases, it may be

advantages to correlate the linear sensor output to match the flow

of the valve. The following plot compares butterfly valve position

with valve flow. A 3

rd

order polynomial is provided to relate sensor

position to flow. Note due to the design of the electronic straight

wastegate, the butterfly valve is on a preloaded mechanism to

minimise binding at the end stops, this results in the sensor

reading past the home positions and for this reason the

calibration sequence with

low

force is essential.

y = -2.1519x

3

+ 3.0586x

2

+ 0.0582x + 0.0326

R

2

= 0.999

Butterfly Position

Flow Percentage

0%

3.3%

3%

3.7%

6%

4.7%

10%

6.7%

20%

14.9%

30%

26.7%

40%

40.8%

50%

55.7%

60%

70.4%

70%

83.4%

80%

93.5%

90%

99.4%

100%

100.0%

0%

20%

40%

60%

80%

100%

120%

0%

50%

100%

Fl

o

w

P

er

centa

ge

Butterfly Position

5

6