4

BASIC TUNING PARAMETERS

It is important that the basic tuning parameters are discussed with a trained professional, please consult your ECU

manufacture. There are a few basic parameters that are worth noting.

Motor polarity is important,

Due to the nature of PID controllers (Proportional-integral-derivative controller) the Electronic

Straight Gate will be targeting a set position, this will move further away if the motor polarity is wrong as it is trying to reach

its setpoint.

Current limitations

, it is important that the Current that is driven through the motor is limited to no more than 20amps for

more than 1 second and 5 amps for more than 5 seconds. It is important that the current values such as the dead band are

correctly set in the ECU to allow for the motor to only be active if needed.

Sensor Diagnostic limits

should be monitored for values that are lower than 0.1V and higher and 2.15V with respect to

the Temperature sensor and 0.1V-4.9V with the position sensor. It is also recommended that safety tuning strategies are in

place to lower temperatures if the eWastegate internally reaches a temperature of 150degC (302degF).

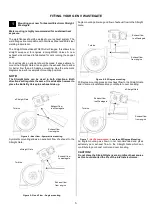

Butterfly Position limits

should be set to target 0% for butterfly closed and 90% for completely open, Since the design of

the end stops is biased to operate better with the butterfly in the closed position it is recommended to avoid opening the

butterfly at full opening.

Boost cut

should be set

to ensure the safety of your engine a sensible boost cut should be set with in the ECU to control

any possible over boost issues that could be detrimentally to your engine.

------------------------------------------------------------------------------------------------------------------------

WHAT’S NEW

The new Turbosmart Electronic Straight Gate is Turbosmart’s addition to its electronic wastegate line-up. A new level of control is

now available with the butterfly valve and offers the option for customers who require another packaging or new level of control.

Control

With the introduction of the electronic motor to drive the Electronic Straight Gate, a new level of control is now available to boost

control, there is a wide range of tuning strategies that can be implemented to better control boost as well as engine protection. This

allows the Engine to maintain much better control over the turbocharger.

Adjustability

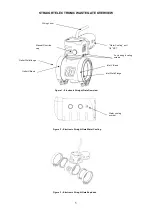

The straight gate now offers 3 options for the motor and body to be mounted in, this is coupled with infinite possibilities of the body

and exhaust piping with the weld flanges. So, if you need the Electronic Straight Gate mounted in the opposite orientation to stop

fouling with parts within the engine bay, there is an orientation that is suitable for the Electronic Straight Gate to operate in. This mixed

without the need of having to remove and reassemble due to changes in base wastegate spring pressure the Electronic Straight Gate

has next level control adjustability of the position of the wastegate butterfly valve.

Upgrades and Servicing

Due to the modular construction, the new range is also upgradeable and completely serviceable, as all components can be removed

or upgraded. Components have been tested for over one million cycles, so reliability is rock-solid.

Flow and Thermal Performance

The new straight wastegate is a world first in its class It features excellent flow properties thanks to our world-leading engineering

and simulation abilities. Thermal performance is a critical key performance factor within the design of all our products. Thermal stability

and longevity are further extended with the liquid cooling ports for further thermal performance if required.