8

Connecting Your Wastegate

The Turbosmart Electronic wastegate comes unterminated with

7 wires.

Wiring Pinout

Revision B (current)

– Wiring

Colour

Description

1 single core

wire each

Large Gauge Red

Motor A tending towards

0%

Large Gauge

Black

Motor B tending towards

100%

Multi Core

Wire

Red**

5V

Black***

Sensor ground 0V

White

Position Signal 0-5V

Blue

(Rev B Only)

*

Unfiltered Signal Output

(Position Output)

Yellow

(Orange

Rev A)

Temperature Signal 0-5V

*Note:

The Blue (unfiltered position signal) is not required for

use & is for development purposes only.

**

Note:

The 5V red wire has no reverse polarity protection, use

only 5V wired in correctly.

**Note:

The sensor ground must be grounded at the ECU

Sensor ground and

NOT

the chassis.

Sensor Voltage Limits

Deg C (Deg F)

Temperature

Sensor

Output (mV)

0 (32)

2630

150 (302)

538

Position Sensor

Target Voltage (V)

Duty Cycle

100% (Open)

0.2-0.6V

~16%

0% (Closed)

4.2-4.60V

~84%

CAUTION!

Turbosmart recommends calibrating the position sensor

before connecting the motor wires to your motor drive.

The two large wires are directly connected to the motor of the

wastegate and need to be connected to high power drives in a

Full bridge configuration like that of an electronic throttle drive

circuit, see your ECU supplier documents for suitable

connections. Turbosmart recommends the eWastegate should

be driven by an External dual H-Bridge, which is at least 20A for

seamless operation.

Connect the small Red Wire to a 5V power source from your ECU

as well as the Black wire to Sensor ground. Connect the white

wire to a 0-5V analogue input on your ecu as well as the orange

temperature sensor signal. The blue wire (Revision B only) is an

unfiltered position output signal for development purposes - This

can be left unterminated.

CAUTION!

Whilst the temperature sensor is not required for operation

it is recommended for activating failsafe protocols.

Ensure all connections are high quality and away from any

heat source.

It is important during the setup of the eGate, that some

precautions are taken to ensure that the unit does not

malfunction. Firstly, the output from the ECU should be

limited to 15%. As well as an inline fuse (5A-10A) or breaker

to protect the eGate. Once correct operation has been

verified the fuse and limits can be removed.

Calibration

CAUTION!

Disconnect the motor wires to prevent accidental spin up.

To calibrate the electronic straight gate firstly the manual override

cap must be removed to allow access to the manual override. A

non marking 14mm is required to remove the cap from the body.

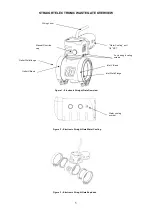

Figure 12

– Manual Override

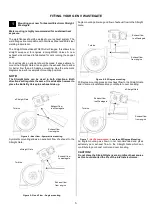

Using a ¼” drive extension with a 5mm socket, turn the manual

override in a clockwise direction with your fingers until the

mechanism stops rotating. In this position the butterfly valve

should be home against the valve seat and will be your 0%

position.

Figure 13

– ¼ Drive extension with 5mm socket manually

adjusting.

3

3

4

3

Valve OPEN

Valve CLOSED

14mm Manual Override Cap