47

TTP-243 Plus/ 243E Plus/

342 Plus Bar Code Printer

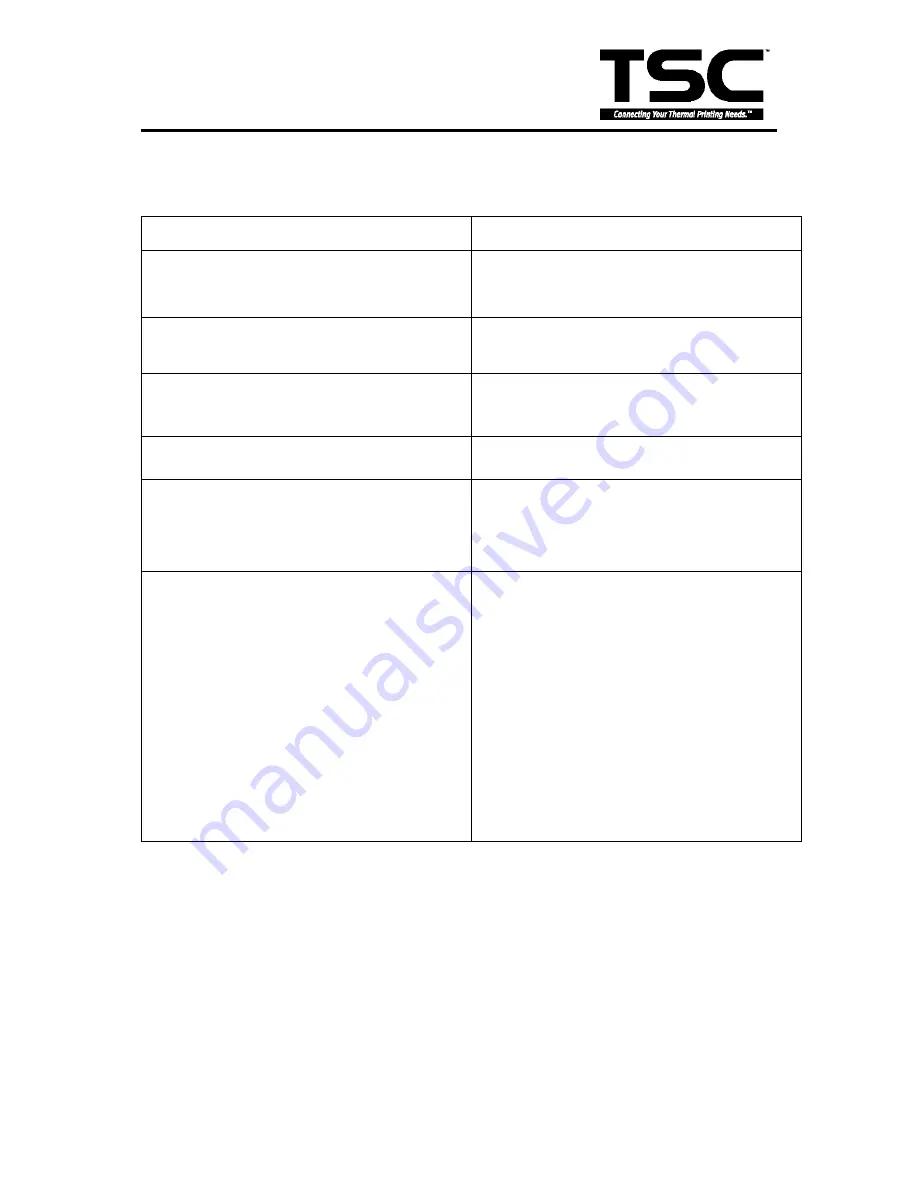

5.2 Trouble Shooting

Problems

Solutions

1. Ribbon does not advance.

Check the printing mode setting and reset the

printer.

2. Poor print quality.

Clean the print head.

Adjust the print density setting.

3. Only prints diagonal pattern in the self-test.

Ribbon and paper are incompatible. Use a

different type of ribbon.

4. Power indicator light does not illuminate.

Check the connection of serial port cable.

5. On-line indicator light does not to illuminate.

Check the DIP switch setting and reset the

printer.

Check that power cord is properly connected.

6. Error indicator remains illuminated.

Out of paper or out of ribbon.

Check the DIP switch setting

Check the paper core, make sure it is installed

on the ribbon rewind spindle.

Press the FEED key. The error message will

be printed out on the print media or sent out

through RS-232 port.

If there is no problem with direct thermal

printing, but error occurs in thermal transfer

printing. Please check the encoder of the DC

motor.