6

Note:

For ANSI Class 900 and above valves,

valve sizes up through 1.5-inch, the seat

retainer window should be placed in the body

with the window facing toward the valve

ports. For valves 2-inches or greater in size,

the bar of the retainer should face toward the

valve ports.

6. For air-to-open valves, place air under the

actuator piston to retract the plug.

7. Let down the plug and body squarely into

the body. Take caution as not to scratch the

plug as it enters the body.

8. To properly align the seat ring and plug, first

bring the bonnet bolting to finger tightness.

a. If the actuator is pneumatic, apply air

pressure above the piston to seat the

plug in the seat ring, then skip to step 9.

b. If the actuator is electric or hydraulic,

move the actuator stem down until it is

fully extended. Then retract the actuator

stem 1/8-inch/3.175-mm. Mount the

stem clamp onto the plug stem/actuator

limit switches according to the operating

manual of the actuator.

Note:

The following step (9) pertains only to

valves with pneumatic actuators. In the case

that an electric or hydraulic actuator is used,

return the plug to the mid stroke position and

proceed to tighten.

CAUTION:

For electric or

hydraulic actuators, failure to

return the plug to a mid stroke

position will cause damage to

the actuator and/or the valve

while the bonnet is being

tightened.

9. If the valve is air-to-close, skip this step and

continue to step 10. Check for proper plug

seating in air-to-open valves as follows: If

proper seating occurs, the bonnet flange

will be forced up against the finger tight

body with such force that it will not be

possible to wriggle the flange. If improper

seating occurred, the bonnet flange can be

wriggled with light hand force. If this

occurs, place air under the actuator piston

and retract the actuator to approximate

mid-stroke position. Turn the plug out of

the actuator stem one additional thread and

repeat the seating procedure described

above. When the bonnet flange becomes

tight against the finger tight body bolting,

the plug is then properly seated.

10. For pneumatic actuators, put the plug in

the closed position. For electric, hydraulic,

or mechanical actuators, move the plug to

the mid-stroke position. Tighten the bonnet

flange bolting in such a way that will

maintain the bonnet flange square (or

parallel) with the body. Tighten the first bolt

1/6 of a turn, then,tighten the bolt directly

opposite 1/6 of a turn and so on around the

flange. Tighten all the bolts firmly and

evenly to compress the bonnet gasket and

seat the bonnet. Torque the bonnet bolts to

the suggested torque values in Table 4.

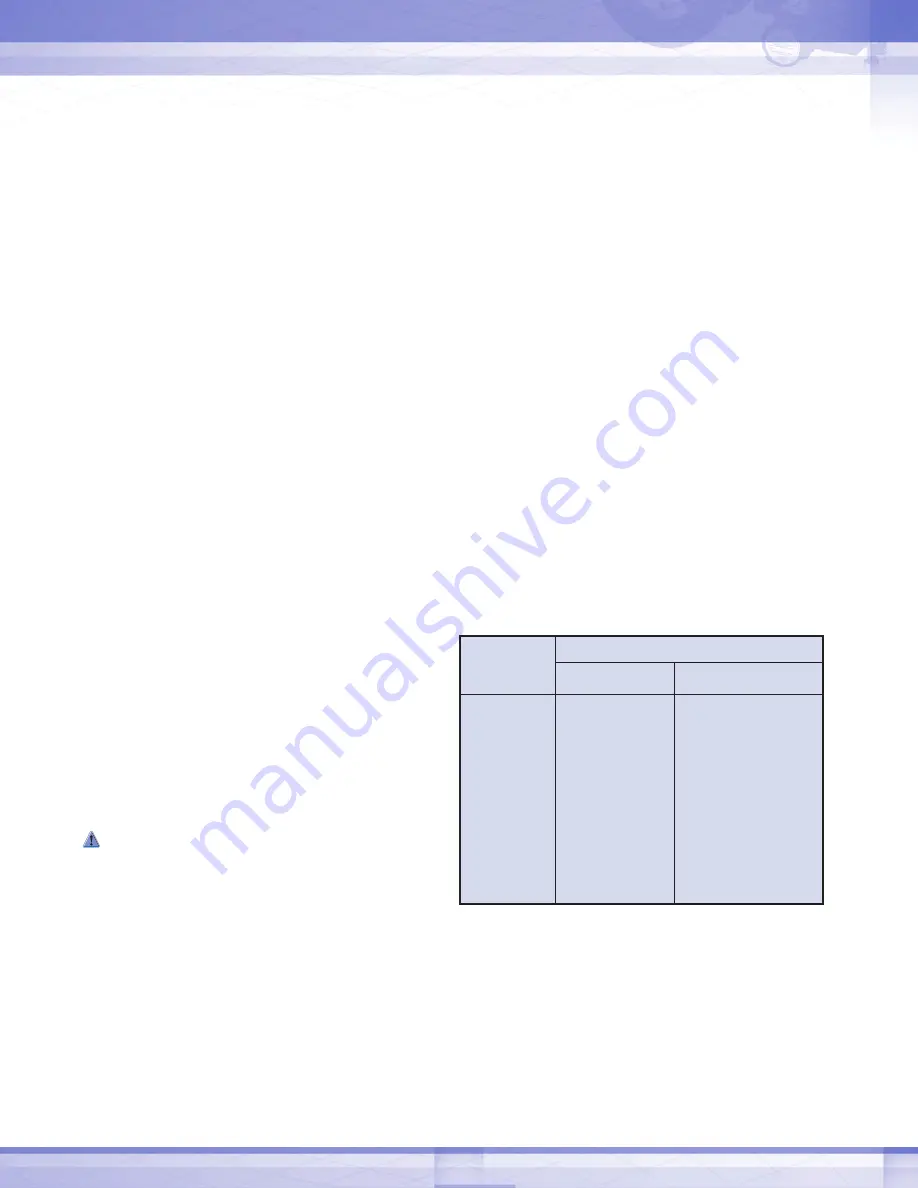

Table 4: Suggested Bonnet Bolting Torque

Values (ft. lbs. /Nm, ± 10%)

11. To seat the plug, apply air over the piston.

For throttling valves, adjust the stem clamp

so that, with full instrument signal to the

positioner, the full signal scribe line on the

positioner cam points to the center of the

cam roller bearing.

Op

G

L

G

lobe Control Valve

Bolt Size

(inches)

5/8

3/4

7/8

1

1 1/8

1 1/4

1 3/8

1 1/2

1 5/8

1 3/4

1 7/8

2

Carbon Steel

80/108

140/190

230/312

350/475

510/690

730/990

990/1342

1320/1790

1710/2318

2170/2942

2700/3660

3350/4542

Stainless Steel

50/68

90/122

150/203

220/298

330/447

460/624

630/854

840/1140

1080/1484

1400/1898

1700/2305

2100/2847

Bolt/Stud Material