5

CAUTION:

In the case that re-

machining is necessary, be

sure to protect the stem during

turning. Insure concentricity of

the seat surface with the plug

stem (or outside diameter of the

seat ring, if machining the

seat).

7. To replace packing or change the packing

box configuration, push out the packing,

spacer, and guides with a dowel of a similar

size as the plug stem.

WARNING:

For valves equipped

with separable end flanges, do

not machine the body gasket

surfaces. Machining could

cause gasket leakage and

failure of the valve.

8. In the case that separable end flanges

need to be removed, file off tack welds or

pull rivets behind the flanges.

CAUTION:

If separable end

flanges and spiral wound

gaskets are used, use gaskets

with outer back-up rings.

Failure to do so could result in

excess stress in some

applications.

Note:

To prevent flanges from dropping off

during shipping, a tack weld or stainless

steel rivet has been installed behind the end

flanges.

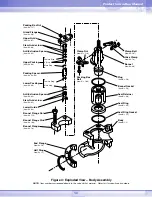

Body Reassembly

To reassemble the valve body, refer to Figure

4, and continue as follows:

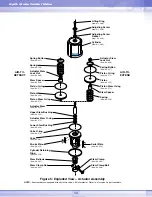

1. In the case that packing was removed, refer

to Figure 2 and install new packing exactly

as shown. Be sure to leave at least 1/8-inch

at the top of the packing box for the top

guide to enter. Different spacer lengths

allow a wide variety of packing

configurations, such as twin seal and

vacuum pressure packing.

WARNING:

Valves with extended

bonnets or metal bellows seals

must not have lower packing

installed. Rather, lower packing

rings should be installed with

the upper set.

Wherever graphite guides are used, the

graphite liners should be replaced each

time the valve packing is replaced. Under

no circumstance, should the valve be

replaced without graphite liners and guides.

2. Insert the plug stem into the packing box,

being sure not to scratch the stem or

guides.

3. Turn actuator back onto the plug, without

turning the plug inside the bonnet. Be

certain that the gland flange and bonnet

flange are in place prior to engaging the

plug stem and actuator stem threads.

Note:

To prevent galling, do not let the gland

flange come into contact with the polished

plug stem.

Leave about three to four plug stem

threads exposed. Attach yoke clamp and

gland flange bolting. When working with

valves using a 2-inch spud, make sure that

the half rings are in place between the yoke

and bonnet. Tighten yoke clamp bolting

firmly.

4. Install new seat gaskets as well as a new

bonnet beveled edge up for Teflon gaskets.

5. Introduce the seat ring into the body with

the step side down. Place the seat retainer

into the body with the thin end of the

cathedral window down.

Product In

s

truction Manual