8

Note:

The actuator stem bushings are

pressed into the yoke; it is not necessary to

remove the bushing in order to replace the

O-ring.

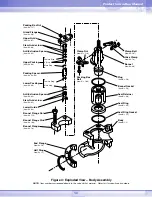

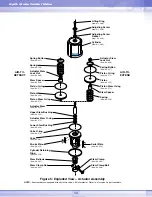

Actuator Reassembly

For actuator reassembly, refer to Figure 5.

Continue as follows:

1. All O-rings should be replaced and the new

ones should be lubricated. Most O-rings

can be lubricated with a silicone lubricant.

(Do not use a silicone lubricant on silicone

O-rings)

2. Be certain to clean and lubricate all internal

parts before beginning reassembly.

3. In the case that the actuator stem has been

removed, replace the piston stem O-ring,

and reassemble the piston and actuator

spacer on the actuator stem according to

the valve’s air-action. If air-to-close, the

spring button has to be inserted under the

actuator stem-retaining nut. Tighten the

retaining nut firmly.

4. For air-to-close configurations, place the

spring under the piston and insert the

actuator stem through the yoke – be careful

not to gall the stem or bushings. Be sure

that the spring is retained in the groove on

top of the yoke. For air-to-open

configurations, insert the actuator stem

through the yoke and place the spring and

spring button above the piston.

5. Mount the cylinder and make certain that

the yoke is pushed deep enough into the

cylinder for the retaining ring to be installed.

6. Reintroduce the retaining ring by pushing it

into the groove a section at a time until it is

in place. Replace the stem bellows and the

stem clamp.

7. Reinstall the gasket and adjusting screw

using a new adjusting screw gasket. The

adjusting screw should be tightened only to

the point where it creates an air seal with

the gasket.

Note:

For air-to-open configurations, be sure

that the hole in the spring button is directly

centered under the adjusting screw.

CAUTION:

Do not put a

screwdriver through the lifting

ring to reinstall the adjusting

screw; doing so may damage

the weld between the lifting ring

and adjusting screw.

8. Apply air over the piston and place the

actuator subassembly, making certain that

the gland and bonnet flanges are in place,

onto the valve. If the valve has a 2-inch

spud, make sure that the half rings are in

place between the yoke and bonnet.

Connect the plug stem and actuator stem

threads. Cautiously turn the actuator

clockwise until the plug stem is engaged 3

to 4 turns.

CAUTION:

Do not allow the plug

to turn on the seat to avoid

possible stem and/or seat

galling.

9. For air-to-open valves, apply air under the

piston, for air-to-close valves, apply air over

the piston, do either in order to prevent the

plug head from touching either the seat or

the bonnet. Continue turning the plug stem

into the actuator stem until 2 to 3 plug stem

threads remain exposed.

CAUTION:

To prevent galling of

the polished plug system, do

not allow the gland flange to

make contact with the polished

plug system.

CAUTION:

Do not allow the plug

to turn on the seat so as to

prevent possible stem and/or

seat galling.

Op

G

L

G

lobe Control Valve