DRAIN LINE

The drain line should be run from the drain

connection, sloping at least 4” vertical drop for

every foot of horizontal distance . A trap outside

the room will allow proper draining throughout the

line. Connection should be made to proper drainage

facilities that comply with local codes and regula-

tions.

In freezers, to prevent drain line freeze up prob-

lems, the line must be heated and insulated. A heat

input of 20 W per foot in a 0°F room and 30 W

per foot in a -20°F room is usually satisfactory.

Once the line has been completed , double check

the slope in the drain pan to ensure proper drainage

(prevention of ice build-up on pan).

PIPING

Refrigerant line sizes are important and are not

necessarily the same size as the connections at the

condensing unit or evaporator. If in doubt refer to

a recognized source. (Manufacturer’s Engineering

Manual, Ashrae Manuals, etc.)

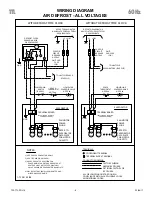

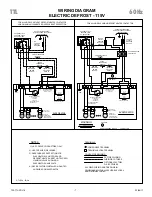

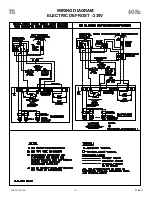

WIRING

Wire system in accordance with local codes and

regulations. A 36” cord is provided for single fan air

defrost models (AD). Multiple fans have a junction

terminal box for conduit connections.

INSTALLATION INSTRUCTIONS (CONT’D)

When fan delay thermostats are installed the fans

may not start up until the coil temperature

reaches approximately 26°F. On initial start up it may

be necessary to bypass (jumper) this control

temporarily until the coil is cold enough.

SYSTEM CHECK

Before Start Up:

1. Ensure wiring is in accordance with codes.

2. Refrigerant lines are properly sized and routed.

3. Thorough leak check, evacuation and dehydration

has been performed.

4. Drain line has been checked for free flow.

After Start Up:

1. Fan has been checked for correct air flow and no

obstructions.

2. Expansion valve superheat has been checked for

proper operation. (Superheat of the coil should be

around 5 to 6°F for a 10°F TD.)

MAINTENANCE

The unit should be periodically inspected for any dirt

or build up on the fin surface and cleaned if

necessary with a soft whisk or brush.

The fan motor is permanently lubricated and should

not require service.

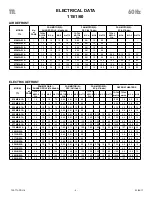

TTL

60Hz

System

Model Number

Date of Start-Up

Serial Number

Service Contractor

Refrigerant

Phone

Electrical Supply

PROJECT INFORMATION

23/06/17

T30-TTL-PDI-16

- 14 -