installed at the housing, ITEM 2, will pro-

vide an indication of the filter being

plugged; pressure reading over 4 psi.

maybe an indication that the filter needs

replacement. At higher discharge pres-

sures the discharged air quality will

decrease and the vacuum pump

absorbed power will increase.

To replace the oil demister filter, simply

disconnect the oil scavenger line,

remove the cover, ITEM 25, remove the

used filter element, apply a gasketing

material over the gasket faces of the

new filter and place the latter in the

housing, put in place the cover and the

scavenger line.

– 30 –

During operation it must be avoided to have sudden and frequent variations from

high to low vacuum. (e.g. suddenly opening the suction valve when the pump is

operating at pressures lower than 150 Torr). This would flood the pump creating

high power absorption that would put heavy stress on the motor and coupling.

Par ticular attention should be put on the quantity of the ser vice liquid flow. The

flow will depend upon the type of installation (see section 9), the pump size,

and/or the desired temperature rise. The flow of ser vice water at 15 °C, for stan-

dard pumps and normal operating conditions at various vacuum levels, is listed

on the specific pump cur ves and/or on table 3 of section 9.7. Usually the tem-

perature rise of ser vice water, when handling dr y air at 68 °F, is approximately 10

°F. When condensable (e.g.: vapours) are present in the gas stream the heat load

to be removed by the ser vice water will be higher, therefore the ser vice water tem-

perature rise will be higher. The ser vice liquid flow and its temperature will affect

the pump per formance. Generally the low ser vice liquid flow will decrease the

pump capacity, while a high ser vice liquid flow will increase the absorbed power

by flooding the pump (see section 17 for information and calculations). Hard ser v-

ice water will generate lime build-up inside the pump. The severity of the deposit

will var y with the water temperature. Lime or mineral deposits on the sur face of

the internal pump components will cause an increase of absorbed power, wear of

the components and eventually will seize the pump. It is recommended to moni-

tor the water hardness and, if too high, treat the water. If there are no alternatives,

there should be periodical flushing of the pump with a solution that will remove

the specific deposits, or the pump must be periodically disassembled, cleaned of

all incrustations and re-assembled. Systems with total ser vice liquid recover y

require periodical change of the ser vice liquid contained in the closed loop. The

heat exchanger must be kept well cleaned of all mineral deposits for an effective

thermodynamic heat exchange. During operation, a closed loop system will lose

some of the ser vice liquid, due to evaporation and/or saturation of the discharged

gases. It will be required to periodically make-up fresh liquid into the system. This

operation is not required for those systems that are fitted with a float type auto-

matic make-up valve ITEM 8. This valve requires water at a pressure of approxi-

mately 2 bar. Systems that handle condensable will experience a rise in the level

of the ser vice liquid in the separator. The excessive liquid will be over flowed

through the over flow valve or connection. If the specific gravity of the condensa-

ble is higher than that of the ser vice liquid, the condensable must be discharged

through the separator drain valve ITEM 11, preferably with system not running.

12.1 - “OIL SEALED (DynaSeal

TM

)” SYSTEMS

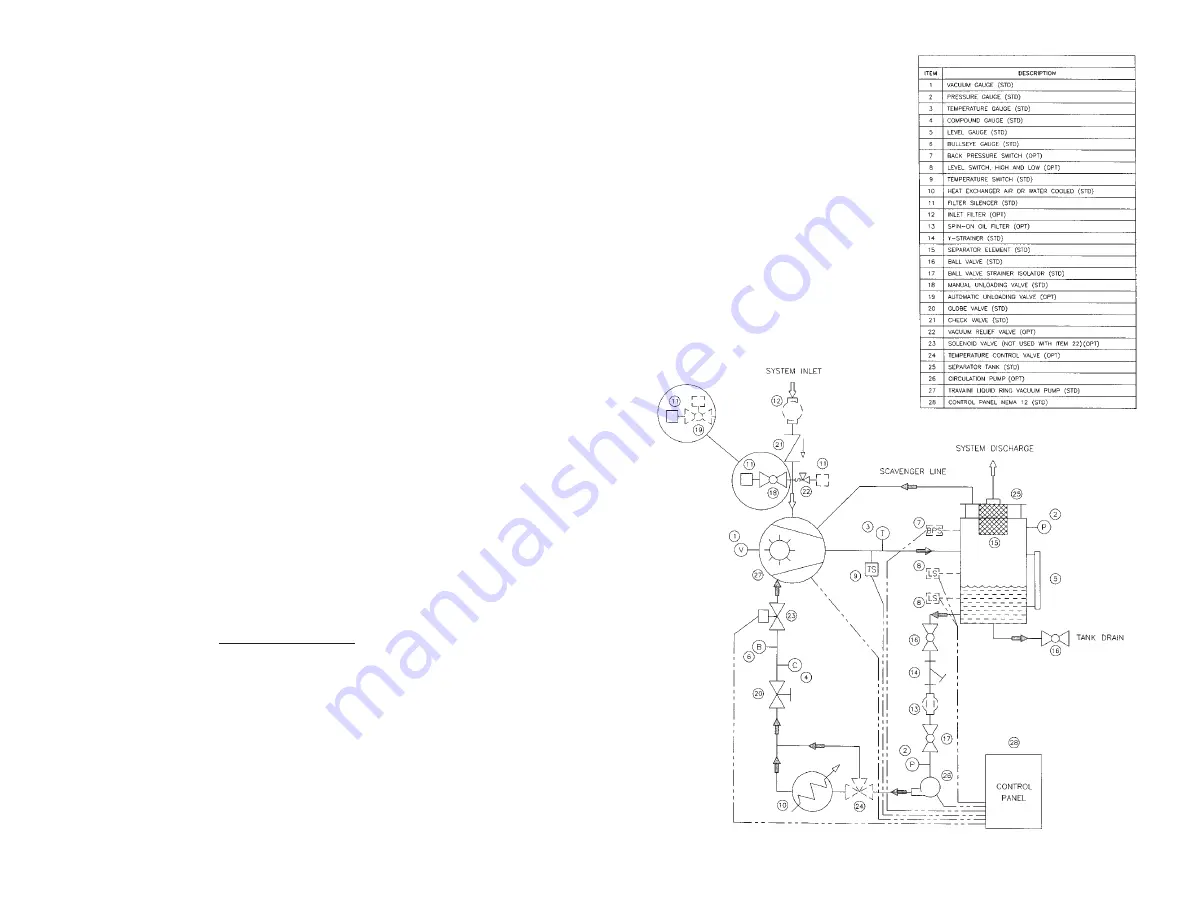

(For ITEM numbers refer to fig. 27 and it’s legend).

It is ver y impor tant to keep the ser vice oil temperature under control when the oil

temperature exceeds 90 °C there is the danger of seizing the pump and the gas-

keting may star t leaking.

Ever y 100 - 200 working hours it is suggested to check the oil level in the oil reser-

voir, make-up oil if necessar y and change the oil ever y 10,000 working hours

(depending upon the use and the application).

Those installations where the handled gases are contaminated with dust or sus-

pended solids that can alter the oil characteristics will require more frequent oil

check and changes.

Condensable vapors, if present during evacuation, can be flushed right through the

discharge of the separator (if they have low boiling point) or, when the system is

idle, can be drained by opening valves, ITEM 16. During operation, the oil demis-

ter filter will be impregnated with oil par ticles; the pressure gauge, ITEM 2,

– 29 –

TYPICAL BILL OF MATERIALS

Fig 27 (General Schematic Drawing)