RTWB-SVN01B-E4

11

Installation Mechanical

Isolation pads

The elastomeric pads shipped are

adequate for most installations. For

additional details on isolation

practices, consult an acoustical

engineer for sensitive installations.

Water piping

Piping connections

C

CA

AU

UT

TIIO

ON

N

To prevent equipment damage,

bypass the unit if using an acidic

flushing agent.

Make water piping connections to

the evaporator and condenser.

Isolate and support piping to

prevent stress on the unit. Construct

piping according to local and

national codes. Isolate and flush

piping before connecting it to the

unit.

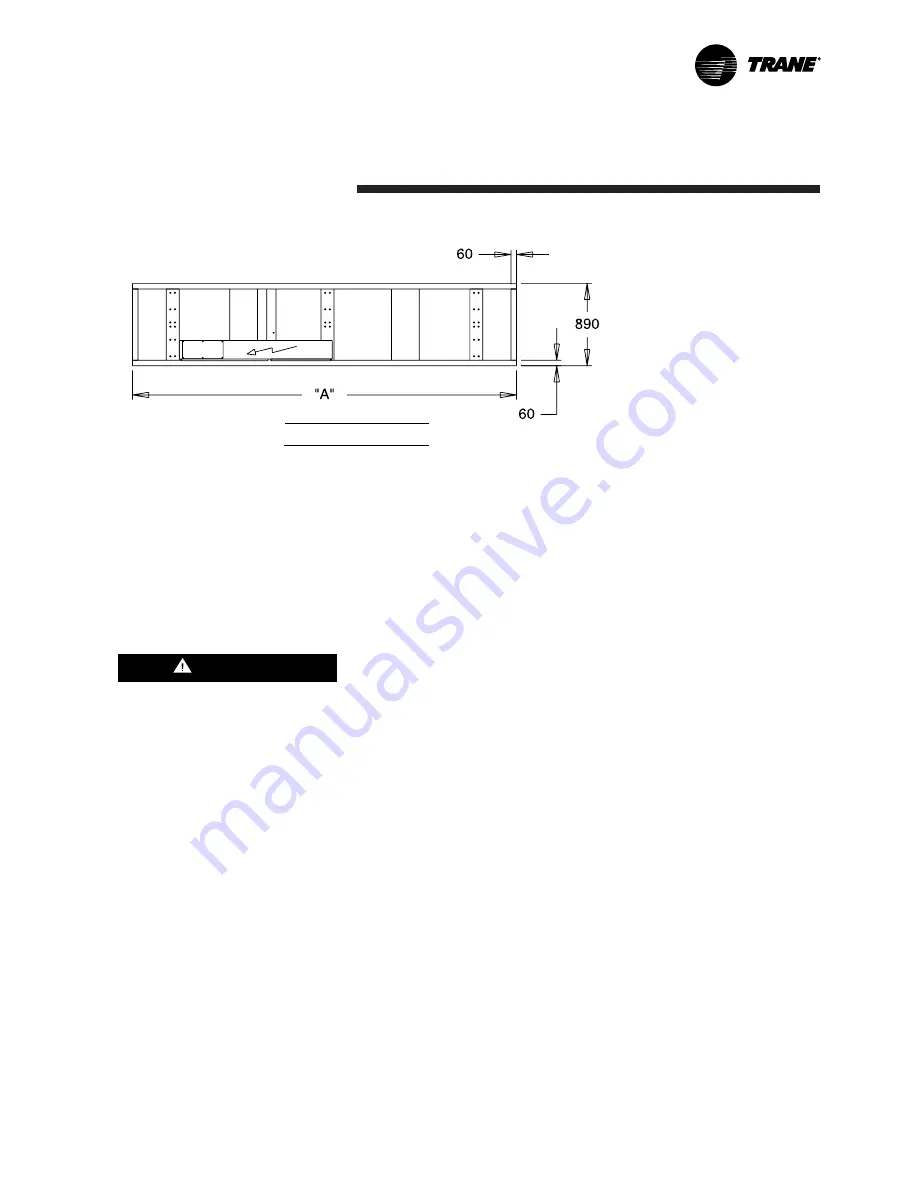

Figure 6 – Isolator pad location

Evaporator water piping

Figure 7 illustrates typical

evaporator piping components.

Components and layout will vary

slightly, depending on the location

of connections and the water

source.

The chilled-water connections are

on the back of the unit, when facing

the control panel.

A vent is provided on the top of the

evaporator at the return end. Be

sure to provide additional vents at

high points in the piping to bleed air

from the chilled-water system.

Install necessary pressure gauges to

monitor the entering and leaving

chilled-water pressures.

To prevent damage to chilled-water

components, do not allow

evaporator pressure (maximum

working pressure) to exceed 10 bar.

Provide shutoff valves in lines to the

gauges, in order to isolate them

from the system when they are not

in use. Use rubber vibration

eliminators to prevent vibration

transmission through the water

lines.

If desired, install thermometers in

the lines to monitor entering and

leaving-water temperatures. Install a

balancing valve in the leaving-water

line to control the balance of the

water flow. Install shutoff valves on

both the entering and leaving-water

lines so that the evaporator can be

isolated for service.

A pipe strainer should be installed in

the entering water line to prevent

water-borne debris from entering the

evaporator.

Dimensions in mm

Size

“A”

207 and 208

2880

210 to 224

4150