Unit Controls and Sequence of Operation

10

SRV-SVX04B-EN

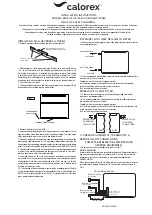

a. Fault and warning indication is seen in two possible

manners on the equipment’s control enclosure. The

HMI display and fault warning lights. The HMI will

display the blinking triangle with exclamation point

and the fault message on the Alarm screen

(Figure 3).

b. A fault results in the Red Light (LT02) remaining

illuminated constantly.

Figure 3.

2. List of System and DH Faults

a. FAULT - D/H WHEEL MOTOR STARTER

PROTECTOR TRIPPED

i. If the desiccant drive motor starter/protector

(MSP1) trips the system is faulted.

ii. The system will go into the shutdown sequence

as described in Section 4, and the system

auxiliary dry contacts close in sequence

(described in Section 2), also process blower

(optional) will purge.

iii. The dehumidifier will be held in the 'Fault'

condition by (PLC1). To restart the dehumidifier

clear the alarm pressing the acknowledge ACK

on the HMI, reset the overload, and go to the

ALARM screen and press the F4 RESET key this

resets the PLC. To restart the system, the

selector switch (SS01) must be moved to the

“OFF” position, then move (SS01) back to the

“AUTO” or “MANUAL” position.

b. FAULT - REACTIVATION MOTOR STARTER

PROTECTOR TRIPPED

i. If the reactivation blower motor starter/protector

(MSP2) trips the system is faulted.

ii. The dehumidifier goes into the shutdown

sequence, as described in Section 4, and the

system auxiliary dry contacts sequence as

described in Section 2 The dehumidifier will be

held in the 'Fault' condition by (PLC1). To restart

the dehumidifier clear the alarm pressing the

acknowledge ACK on the HMI, reset the

overload, and go to the ALARM screen and press

the F4 RESET key this resets the PLC. To restart

the system, the selector switch (SS01) must be

moved to the “OFF” position, then move (SS01)

back to the “AUTO” or “MANUAL” position.

c. FAULT - SUPPLY BLOWER MOTOR STARTER

PROTECTOR TRIPPED/ VFD FAULT (optional)

i. If the supply blower motor starter/protector

(MSP3) trips or the customer-supplied variable

frequency drive (VFD) goes into a Fault, the

system is faulted.

ii. The system will go into the shutdown sequence

(described in Section 4), and the system

auxiliary dry contacts close in sequence

(described in Section 2).

iii. The dehumidifier will be held in the 'Fault'

condition by (PLC1). To restart the dehumidifier

clear the alarm pressing the acknowledge ACK

on the HMI, reset the overload, and go to the

ALARM screen and press the F4 RESET key this

resets the PLC. To restart the system, the

selector switch (SS01) must be moved to the

“OFF” position, then move (SS01) back to the

“AUTO” or “MANUAL” position.

d. FAULT - DEHUMIDIFIER WHEEL ROTATION

i. Limit switch (LS01) is wired normally closed,

and is located inside the dehumidifier wheel

compartment next to desiccant wheel. As the

wheel turns, a cam fastened to the wheel

housing opens this limit switch.

ii. If limit switch (LS01) is not opened once every

600 seconds, a timer in (PLC1) times out the

system is faulted.

iii. The system will go into the shutdown sequence

(described in Section 4), and the system

auxiliary dry contacts close in sequence

(described in Section 2).

iv. The dehumidifier will be held in the 'Fault'

condition by (PLC1). To restart the dehumidifier

clear the alarm pressing the acknowledge ACK

on the HMI, reset the overload, and go to the

ALARM screen and press the F4 RESET key this

resets the PLC. To restart the system, the

selector switch (SS01) must be moved to the

“OFF” position, then move (SS01) back to the

“AUTO” or “MANUAL” position.

e. FAULT – REACTIVATION ELECTRIC HEATER

OVERTEMPERATURE

i. Temperature switch (TS01) is located in the

reactivation Electric Heater and is furnished to

detect extreme temperature level or heat

buildup.

ii. Temperature switch (TS01) is located in the

reactivation “Heated To” duct and is furnished

to detect extreme temperature level or heat

buildup.

iii. The system will go into the shutdown sequence

(described in Section 4), and the system

auxiliary dry contacts close in sequence

(described in Section 2).

iv. The dehumidifier will be held in the 'Fault'

condition by (PLC1). To restart the dehumidifier

Summary of Contents for RSDH0012

Page 13: ...SRV SVX04B EN 13 Fan Curve Figure 10...

Page 14: ...14 SRV SVX04B EN Wiring Diagrams Figure 11 Figure 12...

Page 15: ...Wiring Diagrams SRV SVX04B EN 15 Figure 13 Figure 14...

Page 16: ...Wiring Diagrams 16 SRV SVX04B EN Figure 15 Figure 16...

Page 17: ...Wiring Diagrams SRV SVX04B EN 17 Figure 17 Figure 18...

Page 18: ...Wiring Diagrams 18 SRV SVX04B EN Figure 19 Figure 20...