24

System Start-Up

Sequence of Operation

Standard air cooled condensers function as the outdoor

condensing units for appropriately sized split refrigeration

systems. These units, operating in conjunction with a

matched indoor compressor/evaporator configuration, pro-

vide refrigerant condensing for these systems down to a

normal ambient temperature of 40

o

F. Operation to 0

o

F ambi-

ent is possible with the addition of externally mounted low

ambient dampers.

All condenser fans are direct drive, 26 inch propeller type.

They are driven by 1 HP thermally protected motors.

Condenser fan cycling is accomplished through interlocking

the fan operation with compressor operation (6K1 & 6K2),

and ambient temperature thermostats (1S42 & 1S43) are

used to provide additional fan cycling control. Table 5-1 lists

the condenser fan sequencing data and Figure 5-1 illus-

trates the condenser fan locations with their respective fan

and relay designators.

When wired properly, the unit will start and operate satisfac-

torily as long as the operating temperature is above the

minimum operating temperature listed in Table 5-2.

The condensing unit operation starts and stops automati-

cally when the cooling demand is initiated and terminated

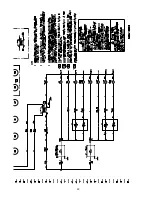

by the cooling circuit interlock relays illustrated in

Figure 5-2.

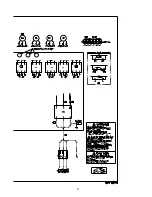

The control components are mounted in the various areas

of the unit as illustrated in Figure 5-3.

Table 5-1

Condenser Fan Sequencing Data

Controlling

Fan

Fan

Fan

Device

ON

OFF

Identification

Customer

Interlock

6K1

6K1

4B2, 4B5, 4B6 (1)

Circuit 1

Closed

Open

Customer

Interlock

6K2

6K2

5B2, 5B5, 5B6 (1)

Circuit 2

Closed

Open

Fan

Stage 1

Temperature

53

o

F

45

o

F

4B3 (1)

Switch

Stage 2

1S42 (2)

73

o

F

65

o

F

4B1, 4B4 (1)

Fan

Stage 1

Temperature

53

o

F

45

o

F

5B3

(1)

Switch

Stage 2

1S43 (2)

73

o

F

65

o

F

5B1, 5B4

Notes:

1. Bold fan identifies fans used on CAUC-D10 & D12 units

only.

2. 1S42 and 1S43 normally-closed contacts open on

ambient temperature drop to "OFF" setpoints.

Contacts reclose on ambient temperature rise

on "ON" setpoints.

Low Ambient Damper Operation

Low Ambient Dampers are available as a factory installed

option or can be field-installed. Dampers are used to extend

the operation of these units from the standard operational

temperatures to a minimum of 0

o

F without hot gas bypass

or 10

o

F with hot gas bypass. (These values apply when

wind speed across the condenser coil is less than 5 m.p.h.).

If typical wind speeds are higher than 5 m.p.h., a wind

screen around the unit may be required. By restricting the

airflow across the condenser coils, saturated condensing

temperatures can be maintained as the ambient tempera-

tures change.

The low ambient damper actuator controls damper modula-

tion for each refrigerant circuit in response to saturated con-

densing temperature.

Low Ambient Thermostat Operation

In addition to the low ambient dampers a two stage low am-

bient thermostat is installed to further restrict the airflow

across the condenser by cycling the 4B1 + 4B6, 5B1 + 5B6

on 100 & 120 Ton units. The final stage thermostats opens

when the ambient temperature approaches 65

o

F and closes

at approximately 73

o

F. The second stage opens when the

ambient temperature approaches 45

o

F and closes at ap-

proximately 53

o

F.

Summary of Contents for CAUC-C80

Page 8: ...8 Figure 3 2 CAUC C80 Unit Dimensional Data Recommended Clearances ...

Page 9: ...9 Figure 3 2 Continued CAUC D10 Unit Dimensional Data Recommended Clearances ...

Page 10: ...10 Figure 3 2 Continued CAUC D12 Unit Dimensional Data Recommended Clearances ...

Page 19: ...19 Installation Continued Figure 3 5 Typical CAUC C80 through D12 Field Wiring Diagram ...

Page 28: ...28 Figure 5 2 Typical Wiring Schematic for 80 through 120 Ton Units ...

Page 29: ...29 ...

Page 30: ...30 Figure 5 3 Typical Control Panel Connections Diagram for 80 through 120 Ton Units ...

Page 31: ...31 ...

Page 36: ...36 ...