17

Installation (Continued)

Leak Testing Procedure

When Leak-testing a refrigerant system, observe all safety

precautions.

Note: Never use oxygen, acetylene or compressed

air for leak testing. Always install a pressure

regulator, shutoff valves and gauges to control

pressure during leak testing.

Trane condensing units are shipped with a Nitrogen hold-

ing charge. If there is no pressure, the unit must be leak

tested to determine the location of leak as follows:

Note: These service procedures require working

with refrigerant, Do NOT release refrigerant to the

atmosphere! The service technician must comply

with all federal, state, and local laws. Refer to

general service bulletin MSCU-SB-1 (latest edition).

Use refrigerant gas as a tracer for leak detection and use

oil-pumped dry nitrogen to develop the required test pres-

sure. Test the high and low side of the system at pressures

dictated by local codes.

1. Close the field supplied liquid line service valve(s) in-

stalled near the evaporator and the compressor dis-

charge service valve to isolate the system's high side

from the low side. Pressure test the liquid line, discharge

line, and condenser coils at pressures dictated by local

codes. Do not exceed 10# above the pressure control

settings.

2. Connect a refrigerant cylinder to the charging port of the

liquid line service valve. Use the refrigerant to raise the

high side pressure to 12 to 15 psig.

3. Disconnect the refrigerant cylinder. Connect a dry nitro-

gen cylinder to the charging port and increase the high

side pressure. Do not exceed the condenser maximum

working pressure listed on the unit nameplate.

4. Use a halide torch, halogen leak detector or soap

bubbles to check for leaks. Check all piping joints,

valves, etc...

5. If a leak is located, use proper procedures to remove the

refrigerant/nitrogen mixture, break the connection and re-

make as a new joint. Retest for leaks after making re-

pairs.

6. Repeat the test procedure for the low side of the system,

charging through the suction pressure gauge port or

through an access provided on the suction line by the in-

staller. Increase the system pressure to 100 psig.

7. If a leak is located, use proper procedures to remove the

refrigerant/nitrogen mixture, break the connection and re-

make as a new joint. Retest for leaks after making re-

pairs.

8. Open the liquid line service valve and the compressor

discharge service valve.

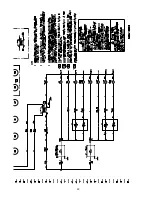

Field Installed Power Wiring

An overall dimensional layout for the field installed wiring

entrance into the unit is illustrated in Figure 3-2. To insure

that the unit’s supply power wiring is properly sized and in-

stalled, follow the guidelines outlined below.

Note: All field installed wiring must conform to NEC

guidelines as well as State and Local codes.

Verify that the power supply available is compatible with the

unit’s nameplate ratings. The available supply power must

be within 10% of the rated voltage stamped on the name-

plate. Use only copper conductors to connect the 3-phase

power supply to the unit.

U S E C O P P E R C O N D U C T O R S O N L Y !

UNIT TERMINALS ARE NOT DESIGNED TO ACCEPT

OTHER TYPES OF CONDUCTORS.

Failure to do so may cause damage to the equip-

ment.

Main Unit Power Wiring

Table 3-3 lists the field connection wire ranges for the main

power terminal block 1TB1. The unit electrical data is listed

in Table 3-4. The electrical service must be protected from

over current and short circuit conditions in accordance with

NEC requirements. Protection devices must be sized ac-

cording to the electrical data on the nameplate. Refer to the

“Power Wire Sizing & Protection Device Equations” for de-

termining;

a. the appropriate electrical service wire size based on

“Minimum Circuit Ampacity” (MCA).

b. the “Maximum Over Current Protection” (MOP)

device.

c. the “Recommended Dual Element fuse size” (RDE).

1. A field supplied disconnect switch must be installed at or

near the unit in accordance with the National Electrical

Code (NEC latest addition). Refer to the “Power Wire

Sizing & Protection Device Equations” (DSS calculation),

for determining the correct size.

2. Complete the unit’s power wiring connections onto the

main terminal block 1TB1 inside the unit control panel.

Refer to the customer connection diagram that shipped

with the unit for specific termination points.

3. Provide proper supply power (with over current protec-

tion) to the Compressor unit and Air Handling unit (“No

Control”, “VAV”, and “Constant Volume”) applications.

For chilled water systems, provide a properly sized

power supply to the circulating pump motor (EVP control

applications). Be certain that these components are

properly grounded.

4. Provide proper grounding for the unit in accordance with

local and national codes.

Summary of Contents for CAUC-C80

Page 8: ...8 Figure 3 2 CAUC C80 Unit Dimensional Data Recommended Clearances ...

Page 9: ...9 Figure 3 2 Continued CAUC D10 Unit Dimensional Data Recommended Clearances ...

Page 10: ...10 Figure 3 2 Continued CAUC D12 Unit Dimensional Data Recommended Clearances ...

Page 19: ...19 Installation Continued Figure 3 5 Typical CAUC C80 through D12 Field Wiring Diagram ...

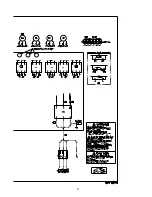

Page 28: ...28 Figure 5 2 Typical Wiring Schematic for 80 through 120 Ton Units ...

Page 29: ...29 ...

Page 30: ...30 Figure 5 3 Typical Control Panel Connections Diagram for 80 through 120 Ton Units ...

Page 31: ...31 ...

Page 36: ...36 ...