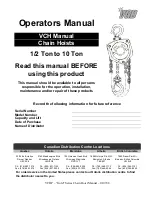

tion. Any use contrary to our instructions is

dangerous and will release us from our lia-

bility as manufacturer.

Do not use the device without having read

these instructions in full and understood them.

These instructions must be kept close to

the device at all times, available to the ope-

rator and the person responsible for main-

tenance.

Follow the safety rules and ensure that they

are followed by others.

2.1 Assembling and anchoring the device

a) Trolley 250 to 5000 kg

IMPORTANT :

Before a CORSO trolley is mounted on a

traversing beam, the strength of the

materials used in the beam must be

calculated by a qualified person.

If the CORSO trolley is to be fitted in a loca-

tion which is dangerous for the operator, the

safety precautions laid down in the labour

regulations must be implemented to remo-

ve all risks not covered in this operation.

CORSO trolleys (up to 2 t) are supplied in

kit form as standard. Before they are moun-

ted on the traversing beam the subassem-

blies must be put together as follows :

• Hold the two side plates of the trolley

either side of the fixing bar, checking that

the screw threads on the fixing bar/side

plates match.

• Rotate the fixing bar continuously to

insert it on both sides into the thread pro-

vided in the side plates.

• When the threaded fixing bar has been

screwed far enough through the side

plates, attach the adjustment handle at

the end of the fixing bar (on the side with

the double drill hole).

• Turn the handle until the distance bet-

ween the running wheels is adjusted to

match the width of the traversing beam.

CAUTION :

The play between the flange of the run-

ning wheel and the edge of the lower

flange of the traversing beam must not

exceed 4 mm for load capacities of up to

2 t, and 5 mm for heavier loads.

• When the adjustment has been correctly

made, the oval part of the anchor point

must be turned to point downwards so

that it can subsequently take the suspen-

sion hook of the hoist.

• Position the copper washer in each hole

to protect the thread and tighten the two

securing screws on the fixing bar.

• Remove the adjustment handle.

Procedure for mounting the trolley on

the traversing beam

When the CORSO trolley has been assem-

bled as described above, it can then be fit-

ted onto either end of the traversing beam.

Do not forget in this case to attach or repla-

ce the end stop on the traversing beam

after fitting the trolley.

If the configuration of the traversing beam

does not allow the trolley to be fitted at the

end, the following procedure must be used :

• Hold the pre-assembled trolley assembly

beneath the beam, keeping a wide

enough gap between the running wheels

to enable the trolley to be positioned on

the beam.

• Place two running wheels on one of the

side plates in contact with the lower

flange of the traversing beam.

• Place the two wheels on the opposite

side plate in contact with the traversing

beam and turn the adjustment handle to

bring the two side plates closer together

and bring the four running wheels to rest

on the lower flange of the beam.

• Adjust the gap between the wheels as

previously indicated.

• Tighten the securing screws on the fixing

rod to prevent the assembly from moving

• Remove the adjustment handle.

For a chain-operated CORSO trolley :

• Check that the hand chain is correctly

positioned on the operating wheel (wel-

ding on the links facing outwards in rela-

tion to the axis of the operating wheel).

• Check that the operating chain is not

twisted.

6

GB