TOYO PUMPS EUROPE

Edition 03.11.2009

- 10 -

3. Other seals

Renew all seals after disassembling.

4. Clearance between impeller and impeller disc

Unscrew the cap nuts (76C). Push the impeller disc (73) against the impeller (72) with the

adjust bolts (85). Unscrew the adjust bolts (85) with half a turn. Fasten the cap nuts (76C)

and the adjust bolts (85). Measure the clearance between the impeller disc and the

impeller. This clearance has to be between 1.0 and 1.5 mm. Verify the clearance with a

gauge. Turn the shaft of the pump by hand. No friction is admitted at all. If necessary,

repeat the operation.

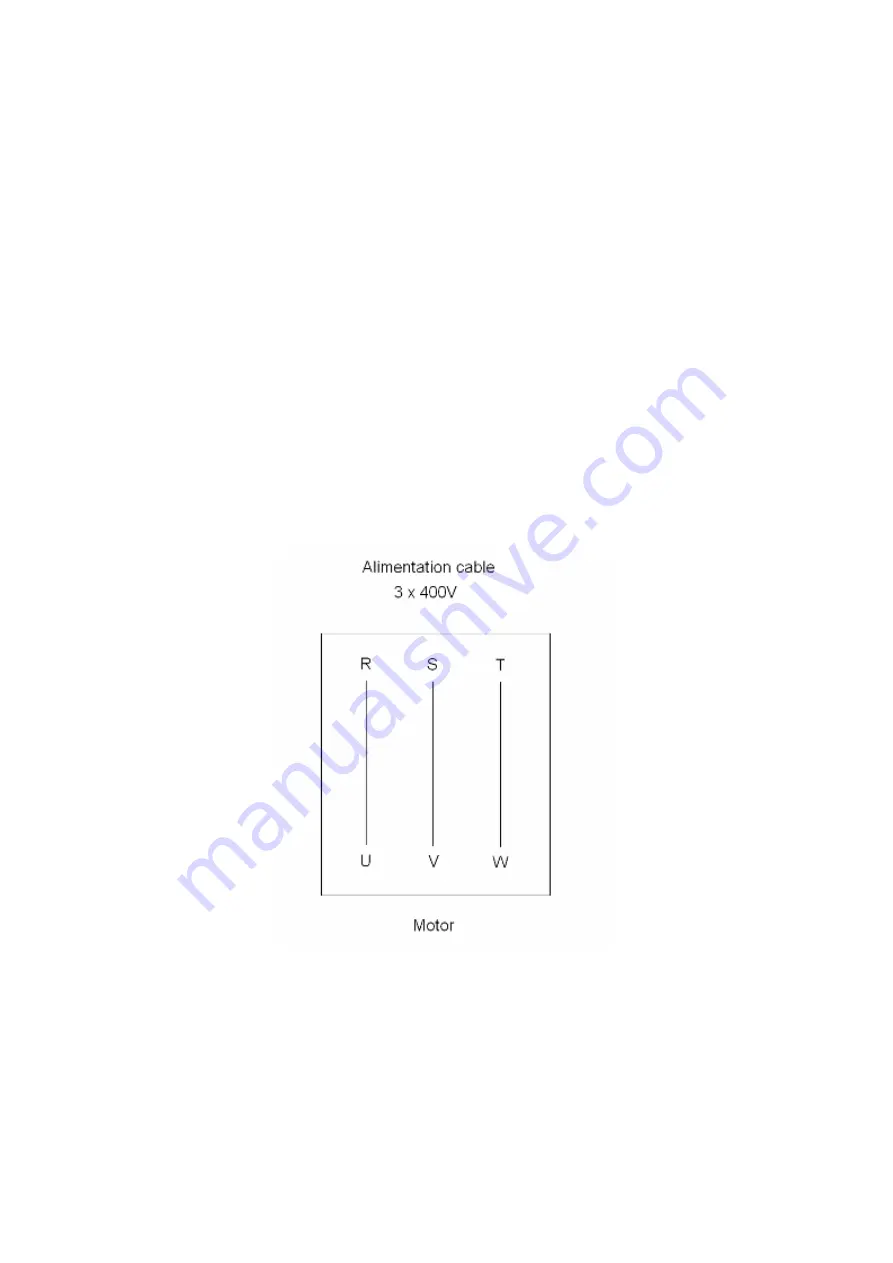

5. Electric connection

Connect the pump as shown on the drawing here below.

N.B. : Do not forget to fill up the under cover with oil. Therefore, use the opening into the

under cover. Type and oil quantity is mentioned in the technical specifications sheet

of the pump.