111011-16 TCVT.FMPV3

This kit uses either Simpson Duravent GS direct vent pipe, Secure Vent

direct vent pipe, Selkirk Direct-temp vent pipe or ICC Exceldirect vent pipe

with a 5” inner pipe and an 8” outer pipe. For part numbers see the table of

venting components on page 10 of this manual. This vent can only be used

as a side wall termination.

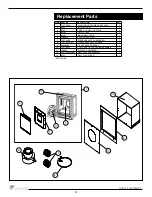

1. Attach the vent adaptor directly to the appliance with the three screws and seal outer

pipe with aluminium tape provided. (Fig. #4)

Note: The inner pipe does not need to be sealed.

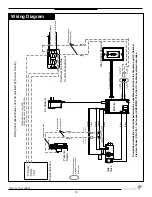

2. Connect one of the high temperature silicone tubes to the upper pressure tap(marked

“LOW”) on the adaptor.(Fig.#4) Secure with the hose clamp provided and route the tube

through any hole back to the control box. This tube will be connected to the “low” side of

the pressure switch inside the control compartment.(Fig.#17) Connect the second tube to

the lower pressure tap(marked “HIGH”) and route to the control box as before. Connect this

tube to the remaining port on the pressure switch.

Tubes may touch unit and be trimmed if required.

Note: Ensure that there are no blockages in these tubes, as this will cause the

control to malfunction.

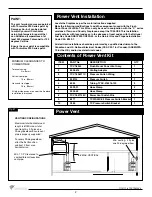

3. Locate the power vent termination following the clearance to combustible table(Page 2),

venting confi guration diagram (Fig. #1 & 2), and terminal location diagram (Fig. #3).

4. Cut and frame a 14 1/2” wide by 14 3/4” high opening. For standard up and out

installations, the opening should be 3/4” lower than the minimum specifi ed in Fig. #2.

Height of the opening will vary with each installation. See Fig. #5.

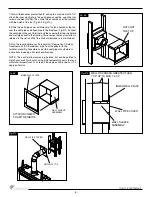

5. Attach the power vent terminal, by securing the outer fl anges on the perimeter of the

terminal to the outside wall; ensure that the terminal is the right way up (exhaust at the

bottom). Once secured to the building, the outer fl anges may be covered with siding/

stucco/etc. up to the level of the perimeter edge. As per local building codes. See Fig. #6.

6. For wall thicknesses 7 1/2” or less, install the inner wall plate supplied over the terminal

as shown in Fig. #6 and secure to the framing. See Fig. #7.

CAUTION:

The adjustable vent restrictor located

on the underside of the fi rebox top

must be fully open.

CAUTION:

This terminal is designed to be

fi nished fl ush to the fi nished outside

wall; under no circumstances

should this terminal be recessed

into the wall past this point.

(Fig. #8)

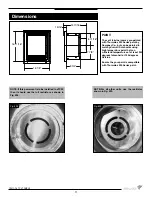

Fig. #4

Power Vent Adaptor.

Part # 5096.816

MUST BE INSTALLED

AT THE UNIT.

UPPER PRESSURE

TAP, MARKED

“LOW”

SECURE WITH

THREE SCREWS

AND SEAL WITH

TAPE

.

LOWER PRESSURE

TAP, MARKED

“HIGH”

4

Horizontal (Side Wall) Venting

Summary of Contents for TCVT.FMPV3

Page 15: ...111011 16 TCVT FMPV3 15 ...