INSTALL THE FUEL TANK & ENGINE

❍

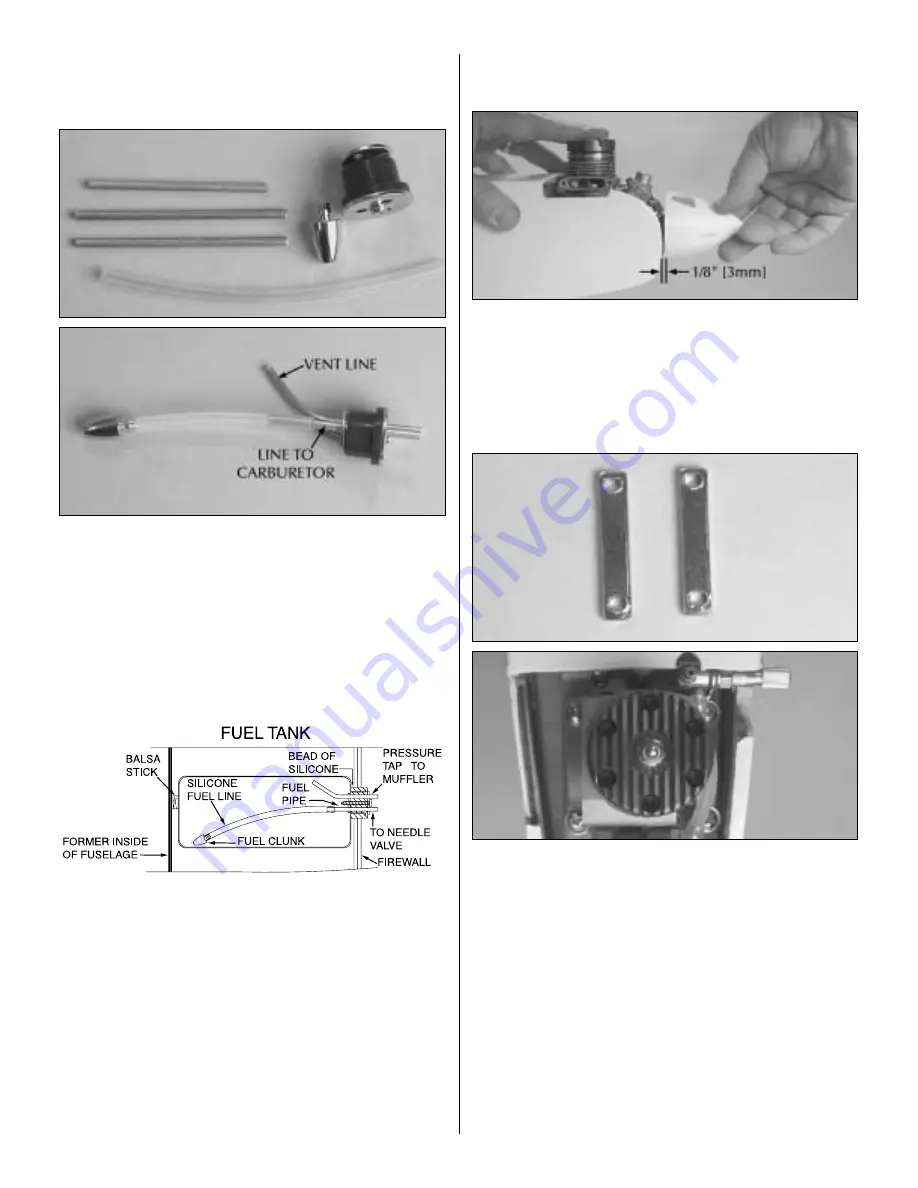

1. Locate the

fuel tank

. Remove the parts from inside of the tank.

❍

2. Assemble the components. Included in the fuel tank

parts are three aluminum tubes. If you will be fueling your

plane with a third line rather than filling the tank through the

carburetor line, you will need to use the third aluminum tube.

If not, assemble the tank as shown with a vent line and

carburetor line. Once assembled, use a fine tip marker and

mark the front of the fuel tank so you can identify which is the

vent line and which is the carburetor line.

❍

3. Insert the fuel tank into the fuselage. Hold the tank in

place either by using silicone glue around the front of the tank

or insert a small balsa stick (not supplied) behind the tank and

glue the stick to the former.

❍

4. Install fuel tubing on the aluminum lines, long enough

to reach the carburetor inlet and the pressure tap on the

muffler.

❍

5. Test fit your engine onto the engine mount. Depending

on your particular brand of engine and whether it has a

remote needle valve you may need to make additional cut-

outs or enlarge the cut-outs that are already made in the

engine compartment. Make the necessary adjustments as

needed to allow your engine to fit.

❍

6. Locate the

plastic spinner

. Remove the nut and washer

from the engine crankshaft and slide the spinner onto the

crankshaft. Place the engine on the engine mount, positioning

it so that there is a least 1/8" [3mm] clearance between the

back of the spinner and the sides of the fuselage. Remove the

spinner.

❍

7. Locate the two engine mounting straps. Install them on

the engine and engine mount by inserting a 4 x 25mm

machine screw, 4mm lock washer and a 4mm flat washer

through the holes in the end of the strap. Attach the strap to

the engine mount. Be careful not to push too hard on the nuts

you glued in the bottom of the engine mount earlier. Doing so

could cause the nuts to fall out of the mount, requiring you to

remove the engine mount to replace the nuts.

❍

8. Locate the remaining 14" [356mm] white pushrod tube.

Roughen one end of the tube with 220-grit sandpaper. Insert

the un-sanded end of the tube into the hole in the top right

side of the firewall. Apply a small amount of 6-minute epoxy

to the end of the white nylon tube. Position the tube so that it

extends beyond the firewall approximately 1/4" [6mm]. Allow

the epoxy to cure.

14