3.

(e)

No. 9 guide check (at REV mode)

(f)

Check for transitional operation

(g)

Recorded & reproduced

envelope check

(h)

Tape damage check

(i)

AFM envelope output max.

point check

1.

Guide roller section damage

Damage at No.8 guide brush

Damage at No.3 guide lower flange

Damage at No.8 guide flange

Damage at No.8 guide flange

Playback mode

Rewinding for synchronous

editing mode

Review mode

Back to step (c) linearity adjustment.

(or Slider assembly replacement)

Back to step (a) ACE head assembly

rough adjustment.

(or Pinch lever replacement)

Back to step (f) check for

envelope operation.

(or Tension lever replacement)

Back to step (e) No.9 guide lever

check or (a) ACE head assembly

rough adjustment.

(Pinch lever, No.9 lever,

Capstan motor replacement)

Back to step (c) linearity adjustment.

Back to step (c) linearity adjustment.

(or slider assembly replacement)

OK

NG

Checks for Hi-Fi models only.

Azimuth adjusting screw

ACE head

position securing

ACE height

adjusting screw

ACE head

Tilt adjusting screw

ACE head adjusting slit

(Insert a slot-type screwdriver.)

(A)

(B)

2.

4.

Damage at guide roller section

Head assembly (cylinder)

assembly replacement

S, T slider assembly replacement

ACE head assembly replacement

Capstan motor assembly

replacement

Pinch lever assembly replacement

(a)

ACE head assembly

rough adjustment

AUDIO HEAD HEIGHT

ADJUSTMENT (AUDIO

HEIGHT ADJUSTING SCREW)

(b)

Playback phase adjustment

Adjust as described in the Electrical

Adjustment Section (Servo circuit.) in

each service manual.

Tension lever assembly replacement

Impedance roller replacement

FE head replacement

(c)

Linearity adjustment

(S, T guide roller)

1. MAXIMUM ENVELOPE

OUTPUT

1. AUDIO HEAD HEIGHT FINE

ADJUSTMENT

1. TAPE WRINKLE CHECK

2. NO. 9 GUIDE ADJUSTMENT

2. ENTRANCE SIDE ENVELOPE

ADJUSTMENT

(Note 1)

Clutch gear assembly replacement

Reel table replacement

(d)

ACE head fine adjustment

OK

No.8 guide flange

Tape

Tape

Audio head

OK

NG

b

d

a

c

(S-VHS model)

(Non S-VHS model)

NG

1.

AUDIO HEAD TILT ADJUSTMENT

(TILT ADJUSTING SCREW)

2.

c/a

≥

0.75

b,d/a

≥

0.63

b,c,d/a

≥

0.75

5.

NG

b

d

a

c

(S-VHS model)

(Non S-VHS model)

c/a

≥

0.75

b,d/a

≥

0.63

b,c,d/a

≥

0.75

Playback the tape recorded in

SP mode. Align position of the

upper end of tape and that of

the audio head.

Playback the tape in SP mode

continuously. Adjust Audio head

tilt screw so that tape runs along

lower flange of No.8 guide

AUDIO AZIMUTH ADJUSTMENT

(AZIMUTH ADJUSTING SCREW)

3.

Playback 7 kHz audio signal on

alignment tape and adjust for

max. output.

ACE HEAD POSITION

ADJUSTMENT

4.

Playback video envelope

signal 2MHz (A ch) on

alignment tape in SP mode.

Reset tracking control at its

center. Adjust ACE main base

to obtain max. output.

Playback the white video

signal on the alignment tape.

Trigger scope with switching

pulse.

Adjust tracking control for maxi-

mum envelope output by

pushing tracking up/down

buttons.

Playback stereophonic

alternative recording signal

(300-500Hz) on alignment tape.

Turn the Audio height adjusting

screw until audio envelope

signal becomes as flat as

possible.

2. AUDIO HEAD TILT FINE

ADJUSTMENT

4. AUDIO HEAD AZIMUTH

FINE ADJUSTMENT

Playback alignment tape in CUE

or double speed mode.

Adjust Audio head tilt until tape

runs along lower flange of No.8

guide.

3. AUDIO HEAD HEIGHT CHECK

Playback signal as described in

step 1, make sure audio

envelope signal becomes as flat

as possible.

If tape travels out of upper/lower

flange as shown above, pinch

lever or capstan motor or No.9

guide lever is defective.

Replace the defective part (s).

Playback 7 kHz audio signal on

alignment tape.

Turn the azimuth adjusting

screw to obtain maximum

output.

5. AUDIO HEAD HEIGHT

RE-CHECK

Repeat same step as step 3.

Playback T-160 tape in

Review mode.

6. ACE HEAD POSITION

Set tracking at its center

position pressing tracking

up/down buttons

simultaneously.

Playback white video signal

(SLP mode) on the alignment

tape. Slide ACE main base to

obtain max. envelope.

Playback 2 MHz video signal

(SLP mode) on the alignment

tape.

Confirm that difference from

tracking center is within 3 ms

when maximum envelope is

obtained.

If not, readjust in SLP mode.

Confirm the portion of upper/

lower flange on No.8 guide.

Playback white video signal

(SLP mode) in alignment tape

and set review mode.

Records signals in SP & SLP

modes, using T-120,

T-160 tape and playback

them to check envelopes.

Run T-160 tape in each mode

and check there is no damage

at each guide.

Playback 3 MHz video signal.

400 Hz AFM signal in alignment

tape ST-NF in SP mode.

Check control pulse phase

difference is within ± 3 ms from

that point to AFM envelope max.

point.

Check video envelope max. point

(A-ch).

Change mode from review to

play and check entrance side

envelope rises within 3s.

Check entrance side envelope

rised within 3s, when mode is

changed from slot-in to play.

Adjust S guide roller to readjust

linearity.

Check step 2 and 3 if no good,

replace S slider assembly or

tension lever.

Rotate S guide roller until

entrance side envelope

becomes as flat as possible.

3. EXIT SIDE ENVELOPE

ADJUSTMENT

Rotate T guide roller until exit

side envelope becomes as flat

as possible.

4. LINEARITY CHECK

Press the tracking up/down

buttons alternately, make sure

envelope increases or de-

creases with flat response kept.

(Note 1)

For the linearity adjustment (c),

make sure adjusted value should

be checked with 2 MHz/SP mode

after completion of specified

adjustments using 30 % white (SLP)

signal in alignment tape.

*

VTR applied SP mode only, use

2 MHz (A ch) video signal instead

of white video signal (SLP mode).

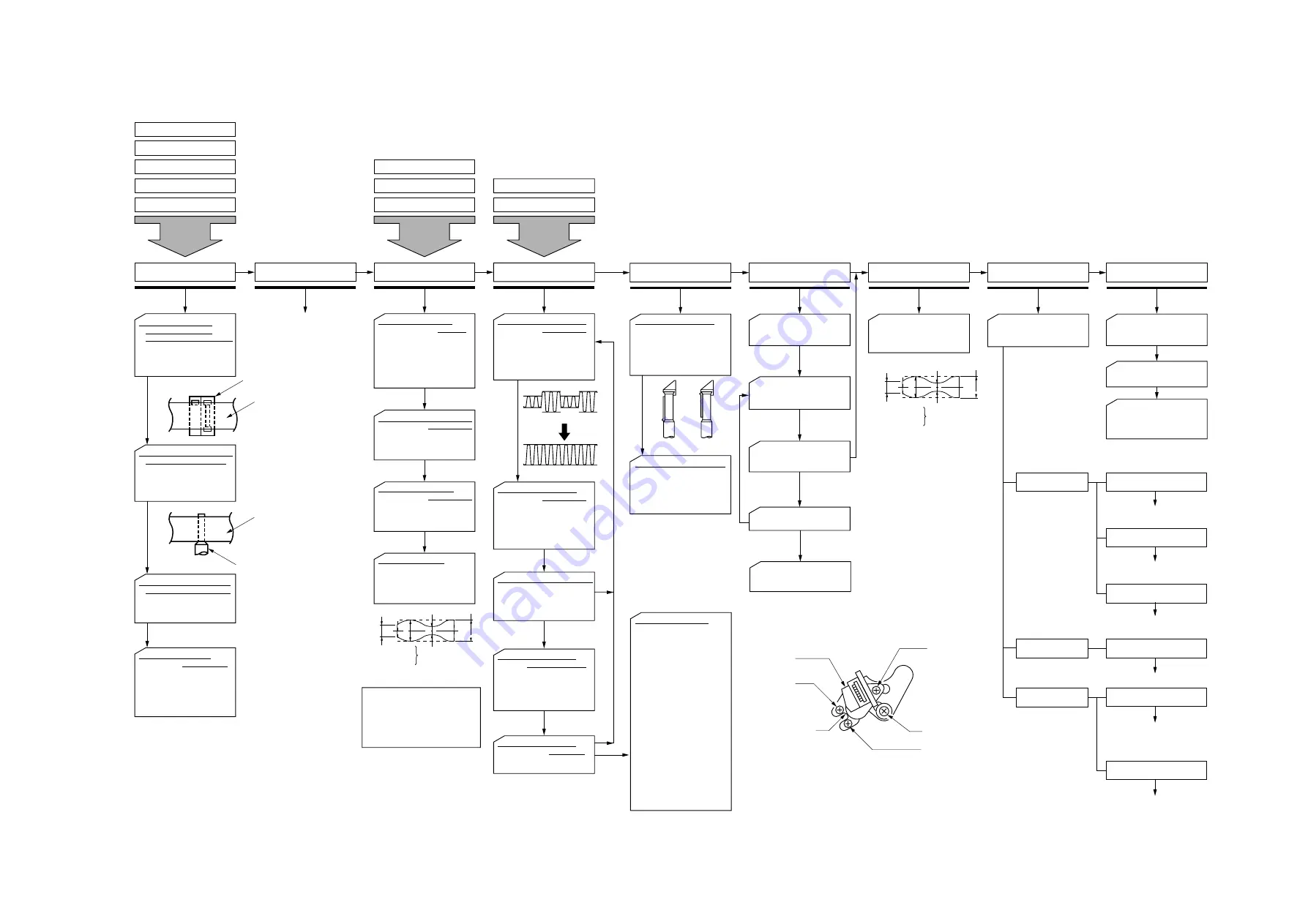

(2) Tape Transport System Adjustment Flowchart

Fig. 1-7-4