– 54 –

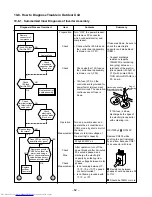

Check

Cause of operation

code

Inverter over-current

protective circuit operates.

(Short time)

Position-detect circuit

error or short-circuit

between windings of

compressor

Current-detect circuit

error

Being out of place,

disconnection or short-

circuit of outdoor temp.

sensor

Disconnection or short-

circuit of exhaust temp.

sensor

Outdoor fan drive system

error

Outdoor heat exchanger

temp. sensor error

Compressor drive output

error, Compressor error

(lock, missing, etc.),

Break down

Error exclusive for

multiple type

Return serial signal has

been sent when operation

started, but it is not sent

from halfway.

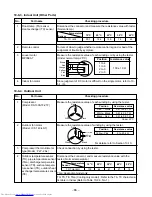

(1) Compressor thermo.

operation

Gas shortage

Gas leak

(2) Instantaneous power

failure

Compressor does not

rotate. (Current protective

circuit does not operate

when a specified time

passed after compressor

had been activated.)

Discharge temp.

exceeded 120°C.

Break down of

compressor

Four-way valve inverse

error (TC sensor value

lowered during heating

operation.)

Operation of diagnosis function

Block distinction

Check

Block

code

Outdoor P.C.

board

Not

displayed

Outdoor P.C.

board

Others

(including

compressor)

Air

conditioner

status

All off

All off

All off

All off

All off

All off

Operation

continues.

All off

All off

Operation

continues.

All off

All off

All off

Operation

continues.

Remarkes

Displayed when

error is detected.

Displayed when

error is detected.

Displayed when

error is detected.

Displayed when

error is detected.

Displayed when

error is detected.

Displayed when

error is detected.

——

Displayed when

error is detected.

Displayed when

error is detected.

Flashes when

trouble is detected

on Return serial

signal, and normal

status when signal

is reset.

Displayed when

error is detected.

Displayed when

error is detected.

Displayed when

error is detected.

——

∗

Judgment and action

Even if trying operation again, all

operations stop immediately. :

Replace P.C. board.

1. Even if connecting lead wire of

compressor is removed, position-

detect circuit error occurred. :

Replace P.C. board.

2. Measure resistance between wires

of compressor, and perform short-

circuit. : Replace compressor.

Even if trying operation again, all

operations stop immediately. : Replace

P.C. board.

Check 5-serial LED.

1. Check outdoor temp. sensors

(TE, TS).

2. Check P.C. board.

1. Check discharge temp. sensor

(TD).

2. Check P.C. board.

Position-detect error, over-current

protective operation of outdoor fan

drive system, fan lock, etc. : Replace

P.C. board or fan motor.

1. Check outdoor heat exchanger

temp. sensor (TE).

2. Check P.C. board.

Check 5-serial LED.

When 20 seconds passed after start-

up, position-detect circuit error

occurred. : Replace compressor.

Check 5-serial LED.

1. Miswiring of connecting wire of A/

B rooms in indoor/outdoor units

2. Check gas leakage.

3. Check disconnection of sensor.

4. Electronic control valve error

1. Repeat Start and Stop with interval

of approx. 10 to 40 minutes. (Code

is not displayed during operation.)

Supply gas. (Check also gas leak).

2. Unit operates normally during

check.

If Return serial signal does not

stop between indoor terminal block

2 and 3, replace inverter P.C.

board.

If signal stops between indoor

terminal block 2 and 3, replace

indoor P.C. board.

1. Trouble on compressor

2. Trouble on wiring of compressor

(Missed phase)

1. Check dischage temp. sensor (TD).

2. Degassing

3. Trouble on P.M.V.

1. Check power voltage.

(220–230–240 V ±10%)

2. Overload operation of refrigeration

cycle

Check installation condition

(Short-circuit of outdoor diffuser).

1. Check four-valve operation.

∗

For 1C and 1E marked with

∗

, refer to the column in page 60.