176

Screw

Comp-nut

Screw

Tool : Ratchet wrench

Screw

Comp-nut

Screw

Tool : Ratchet wrench

TD sensor

Welding part

TD sensor

Welding part

No.

5

Part name

Compressor

Procedure

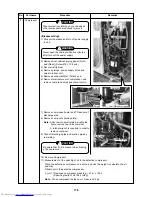

CAUTION

Wear protective clothing on your hands as

other components may cause injury etc.

<Disassembling>

1) Stop unit operation and turn off power supply

to unit.

WARNING

Never open the cabinet while five minutes

after turn off the power supply.

2) Remove front cabinet, piping panel (Front)

and (Rear). (Screw Ø4 × 10 9 pcs)

3) Recover refrigerant.

4) Remove pipings, power supply wires and

wires to indoor unit.

5) Remove soundproof mat. (Total 4 pcs)

6) Remove terminal cover of compressor, and

remove comp-lead wires and comp-thermo.

Remarks

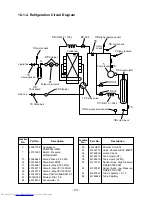

10) Remove Compressor.

11) Measurement of the quantity of oil in the defective compressor.

Place the defective compressor on a scale, and use the weight to calculate the oil

quantity.

Oil amount in the defective compressor:

A [cc] = (Removed compressor mass (kg) – 22.2) × 1042

(Specific gravity of oil: 1042 cc/kg)

Note : When compressor holds no oil, mass is 22.2 kg.

7) Remove comp-case heater and TD sensor at

discharge pipe.

8) Remove comp-nuts (three points).

Note : After remove small plate as right side

figure, remove rear side comp-nut.

A ratchet wrench is required in order to

remove comp-nut.

9) Take off discharge pipe and suction pipe by

re-welding.

CAUTION

Be aware that if oil is present when brazing

a fire could occur.